The wood construction Realizing the consumer trend of wood, it remains a unique, aesthetically pleasing raw material that is an integral part of our lives. Suppose you are quite an architect, a ‘carpenter,’ a ‘wannabe’ carpenter, or enjoy seeing wood used in furniture, wood construction, and other DIY projects. In that case, this post should be interesting for you. So, I invite you to look at the beauty of wood construction and discover this exciting topic together.

Why is wood so great?

However, one crucial thing needs to be discussed before examining the peculiarities of wood construction: why is wood so great? undefined

- Sustainability: Wood is a renewable building material. Proper forest management can help keep our forests abundant and sustain us for the long haul.

- Aesthetics: Each project is distinct precisely because of the individuality of the grains and coloration of each piece of wood.

- Versatility: Wood is a versatile material that can be used in everything from constructing buildings to making furniture.

- Strength and Durability: Wood is a naturally occurring resource that, when properly treated and maintained, can last for several years, perhaps even a century or two.

The Process of Manufacturing and Cutting Wood Used in Architecture

Concerning the wood construction process of an architectural design, the following steps can be observed: Manufacturing and cutting wood.

Whether you are designing your dream house or planning a home improvement project, or you are interested in learning how lumber gets from the forest to the construction site and finally to a beautiful piece of architecture, these are perfectly natural questions that need to be answered.

Once the wood is cut, it undergoes a series of processes from the felling, including forestry, to control the timber supply. This is a crucial step in managing the forests properly, ensuring their sustainability for future usage. Here’s a quick rundown of the initial steps:

- Selection: For this reason, foresters always look at the ecosystem, looking for mature trees to cut to make a timber yield.

- Logging: Selecting trees; the workers at the site fell the selected trees using chainsaws or harvesters and carried the logs to the sawmill.

After getting to the sawmill, real work begins since raw logs do not work for construction purposes in that form. This is where the wood starts to take shape for wooden construction projects. This is where raw wood starts to take shape for wood construction projects:

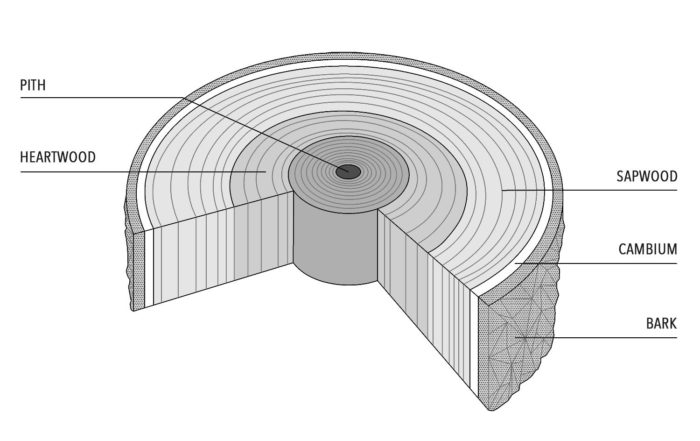

- Debarking: The first step is to sap the logs, which involves peeling the bark off the logs. This may be done mechanically by using mechanical debarkers.

- Sawing: Subsequently, the logs are cut or ripped and sawn into dimensional sawlogs using various saws, such as circular saws, band saws, gang saws, and others.

- Edging: First, the rough lumber is planned further to smoothen the surface and get rid of unwanted humps and to make them straight.

- Trimming: Last but not least, once the required thickness is reached, the lumber is cut to the required dimensions.

Untreated wood serves as a raw material for wood construction, but before that, it has to be adequately dried. This process removes moisture and prevents the wood from bending or cracking during wood construction and design.

Now that the wood is dry and conditioned, the following steps are to cut and carve it into the desired form:

- Rip Saws: These saws are designed to make cuts on the lumber on the lengthwise side of the wood pieces. It is the initial stage of adjusting the lumber size before it is used in any project.

- Crosscut Saws: These saws were wedge-shaped members that assisted in cutting shorter pieces of wood by lateral cutting across the grain.

Precision Cutting - Planers: Planers are used to level woods to achieve uniform thickness and make them even.

- Jointers: They have plain structures to ensure that different wood strands can interconnect perfectly.

- CNC Machines: CNC machines are efficient in carving wooden designs to very high accuracy, and they are used for detailed carving and metal accuracy.

Types of wood used in wood construction:

The uses of wood in architecture, wood construction, and design extend from structural to aesthetic, with knowledge and appreciation of the different types of wood. We will discuss some types of wood used recently:

(1) Glued Laminated Wood (Glulam)

Glulam timber is an engineered wood product that glues timber laminations with moisture-resistant adhesives. This has made it possible to have a material that is robust and durable enough to be used in different wood constructions.

Features of Glulam

Glulam stands out because of its unique features:

- Strength: It has great load-bearing capability and can even be stronger than steel, even when comparing density.

- Durability: Composed of thin layers of lumber, assembled and glued together, glulam does not twist and check as readily as solid sections of lumber.

- Flexibility: It can also be produced and designed in different forms and sizes, even curved ones.

- Sustainability: Glulam, a wood construction material, is not just a strong choice; it’s a responsible one. It originates from renewable resources, making it an option that actively preserves the environment.

Structural Uses

Glulam is often used in structural components because of its strength and stability: Glulam is often used in structural components because of its strength and stability:

- Beams and Columns: Its applications include bolted connections with steel, concrete, and other constructed elements and welded connections for structures with large spans where glulam beams and columns find great use in commercial and residential buildings.

- Bridges: Since glulam is an extremely strong material and can easily be used to form long spans, it is perfectly suitable for constructing pedestrian and vehicular bridges, as shown in the examples below.

- Roof Systems: Glulam is commonly used in the wood construction of roofs, where trusses and rafters are made from it as a support mechanism and possibly as part of the design.

Aesthetic Uses

Glulam, beyond its structural capabilities, is a source of inspiration for architects and designers. Its aesthetic potential is vast, offering the opportunity for unique and striking designs that can transform any space.

- Curved Designs: Architects enjoy this product’s versatility, especially in construction projects where gorgeous spiraling structures, like arched ceilings and wavy roofs, are possible.

- Interior Features: Glulam is applied not only for the development of individual furniture, stairs, and other interior items but also for the application of material that provides excellent tensile strength and, at the same time, an attractive appearance.

(2) Cross Laminated Timber (CLT)

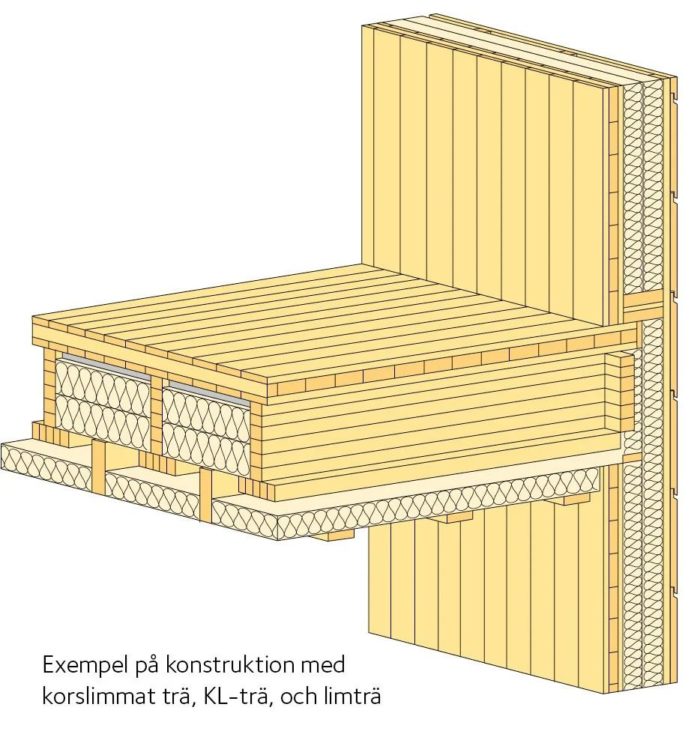

Cross-laminated timber (CLT) is an untreated sawn timber with laminated wood, and its layers are bonded at right angles to each other. This crosswise stacking gives CLT unrivaled strength and stability, which is why it has emerged as a revolutionary technology in wood construction.

Features of CLT:

- Strength and Stability: Cross-lamination produces cross-laminated timber, which creates an excellent mechanical structure for housing and commercial buildings that is as sturdy as concrete and steel.

- Fire Resistance: Surprisingly, through fire tests, CLT shows efficacy because of the char layer that offers a protective cover.

- Thermal Insulation: The fact that CLT is made using solid wood offers insulation benefits, as buildings constructed using this technology are more energy efficient.

- Environmental Advantages: CLT, derived from renewable timber sources, significantly reduces carbon emissions compared to concrete and steel structures. This makes it a highly favorable choice as a green construction material for wooden frameworks.

Structural Uses

- Walls and Floors: CLT panels offer great stability and are generally employed for creating walls and/or floors in a home or a business.

- Roofs: Due to the material used in developing these extended lumber construction panels, they are more likely to be used in roof construction because they are strong and can endure long periods of use.

- Multi-Story Buildings: Amazingly, CLT is being employed in architecture to build more than just a few-story structures. Due to its load-bearing properties, it is also being used to build high-rise structures.

Aesthetic Uses

- Beyond its structural benefits, CLT also offers significant aesthetic advantages: Beyond its structural benefits, CLT also provides substantial aesthetic advantages:

- Exposed Wood Surfaces: CLT panels are also eco-friendly and can be used as structural, fire-resistant, and insulation material with a natural, smooth appearance for interior and exterior surfaces.

(3) MDF (Medium Density Fiberboard)

Medium-density fiberboard is one of the manufactured boards. It is produced by the breakdown of hardwood residuals or softwood residuals into wood fibers. With the liberal use of wax and a resin binder, the fibers are then formed into panels under high temperature and pressure. This creates a dense and smooth material with high density, ensuring it can be used in wood construction for various purposes.

Features of MDF

- Smooth Surface: All MDF products feature a very fine surface, which makes them suitable for painting and other forms of finishing.

- Uniform Density: This makes attaining a high density in its manufacturing process possible, which means equal strength and endurance throughout the entire board.

- Practical Benefits: One of the key advantages of MDF is its ease of machining. It doesn’t splinter when sawn, drilled, or shaped, making it ideal for intricate carving.

- Affordability: Some of the common advantages of MDF that make it gain broad acceptance in many wood constructions include, but are not limited to, the following: MDF is cheaper than solid wood and, therefore, does not require a lot of capital to acquire.

- Eco-Friendly: Many MDF products contain recycled wood fibers, which support environmentally friendly wood construction.

Interior Uses

- Cabinetry and Shelving: It is widely used in constructing kitchen cabinets, bookshelves, and storage units because it can be painted and tailored to meet the required size.

- Wall Paneling: MDF panels are versatile and durable, making them ideal for use in diverse projects, which in turn call for a formal look in interior design.

- Furniture: This is very common, especially regarding tables and bed frames, because furniture makers like MDF due to its reasonable price and versatility.

- Moldings and Trim: Some of its unique features include a non-porous surface, homogenous construction, and hence the ideal finish when making moldings and trims.

Specialty Uses

- Acoustic Panels: MDF is also ideal for acoustic panels to diminish sound transference because of its density.

- Custom Millwork: MDF can also be accurately colored or stained to produce design or form requirements.

- Display Units: MDF is easy to style with different textures and colors, making it a popular product for the production of retail and exhibition displays.

(4) Chipboard and MDP (Medium Density Particleboard)

Chipboard or particle board is an artificial classification of timber derived from wood chips, sawdust, shavings, or splinters bonded with synthetic resin. The mixture solidifies, and it is then compressed and simultaneously extruded to form sheets.

Features of Chipboard

- Cost-Effective: Among all the wooden-based panels, chipboard is less expensive, thus making it an affordable product.

- Smooth Surface: Chipboard boasts a sleek, plain surface, free from complex grain patterns, making it a versatile choice that can be easily integrated into any design scheme.

- Ease of Use: A few of the benefits of using chipboard include: Chipboard is simple to cut, bend, and handle, and therefore, any person constructing with it finds it quite convenient.

- Lightweight: This implies that it is portable, and when it comes to installation, it is also simple to implement.

Interior Uses

- Furniture: Popular uses of Chipboard include manufacturing and assembling furniture like desks, shelves, cabinets, etc.

- Flooring: They function as a subfloor for the floor covering; this is so because they create a firm surface on which carpet, tile, or laminate can be placed.

- Wall Paneling: In addition to its functional use, Chipboard can be used for decorative wall paneling, providing a significant opportunity to improve the look of the interior for relatively little money.

Specialty Uses

- Soundproofing: Also, because it is dense, a chipboard is very useful for sound insulation.

- Exhibition Stands: Due to their ease of use and budget-friendly nature, exhibition stands are extensively employed as temporary display structures for exhibitions.

Wood Construction’s Using

1) Timber frame system

It is one of the earliest forms of wooden structure, where beams and posts of heavy timber were used to form the framework of the building. wood construction technique remains in vogue even today owing to its benefits of durability and looks.

Benefits of the Timber Frame System Several features

1. Strength and Durability

Its strength is another positive factor that may be attributed to a timber frame system. This wood construction utilizes massive timber beams with a robust framework to support heavy loads and bear maximum pressure.

- Resilient Material

- Longevity

2. Aesthetic Appeal

Timber frame systems have the basic asset of being aesthetically appealing. This element of furniture is very appealing since wood is a unique material that boasts natural beauty when used in interior design.

- Natural Beauty

- Architectural Versatility

3. Energy Efficiency

Timber frame systems are also praised for their contractor features and energy efficiency. The use of wood construction allows for the possibility of obtaining a preconditioned building envelope, which ensures low energy consumption and expenses.

- Thermal Insulation

- Sustainability

4. Design Flexibility

Timber frame systems also have another significant benefit regarding design choices.

- Open Spaces

- Customizable

5. Quick Construction

The use of timber frame systems presents certain advantages for construction. Compared to other techniques, the systems can be assembled rapidly. Timber is cut and fabricated before wood construction begins, which saves a lot of time.

- Efficiency

- Reduced Labor Costs.

2) CLT system

Cross-laminated timber is a form of wood construction. It involves placing several pieces of lumber, one on top of the other, in a manner in which the orientations of their grain are at right angles and then joining the wood layers through the use of structural adhesives. This cross-graining technique also improves the material’s stability, strength, and durability.

Features of CLT Systems

1. Exceptional Strength and Stability

Another interesting aspect of CLT is durability, which has helped timber frame structures achieve high strength levels. Cross-graining in CLT construction means that loads are dispersed evenly, making it one of the strongest wood construction techniques imaginable.

- Load-Bearing Capacity

- Dimensional Stability

2. Design Flexibility

CLT systems see vast application possibilities in architectural construction because they permit extensive imaginativeness in wood construction.

- Versatile Applications

- Prefabrication

3. Sustainability

This is one of the major benefits of using CLT in wood construction projects. CLT is sourced from timber, a renewable material, and its fabrication proves less hazardous than that of other conventional building materials.

- Carbon Sequestration

- Energy Efficiency

4. Fire Resistance

Many will be shocked to learn that CLT systems offer excellent fire resistance. The exteriors of the thick timber panels are scorched to ensure the safety of the interior layers and other structural compositions.

- Charring Effect

- Predictable Performance

5. Acoustic Performance

Regarding acoustics, CLT systems combine high sound insulation performance, which is essential for generating good living and working conditions.

- Sound Insulation

- Acoustic Customization.

3) Modular system

More specifically, a modular system in wood construction refers to constructing a system of individual sections or modules in a factory environment. These modules are then shipped to the construction site and stacked in a desired plan to form the structure.

Features of Modular Systems

1. Speed and Efficiency

Another advantage of modular systems is that they are highly valued for wood constructions and are often claimed as one of their significant advantages.

- Rapid Assembly

- Concurrent Processes

2. Cost-Effective Construction

- Reduced Labor Costs

- Minimized Waste

3. High Quality and Consistency

- Quality Control

- Uniformity

4. Design Flexibility

Modular building blocks showcase flexibility to architects, incorporating changes that form unique structures and designs.

- Adaptable Designs

- Scalability

5. Sustainability

Again, one of the strengths of using modular systems as a form of wood construction, especially with wood, is the issue of sustainability.

- Energy Efficiency.

- Eco-Friendly Materials.

6. Safety and Durability

Modular buildings are already safe and built to last since they meet or even exceed the required building codes and standards.

- Structural Integrity.

- Safety Standards.

- © José Tomás Franco

- © José Tomás Franco

- © Adrià Goula

- © Adrià Goula

- © Adrià Goula

- Via Shutterstock

- Image Cortesia de Architecture Studio Nolla

- © Burkhard Walther Architekturfotografie

- © Marcel van der Burg

- © Jack Hobhouse

- © Alison Brooks

- © Leonardo Finotti

- © Geert Van Hertum

- © Photolux Studio (Christian Lalonde)

- © Leonardo Finotti

- © George Cott

- © Jonathon Donnelly

- © Rien van Rijthoven.

- © Rohspace.

- © Filip Šlapal.

- © André Scarpa.

- © Koichi Torimura.

- ©swedish wood

- © Cristina BeltránCadam.

- © i29 l interior architects.

- Ateljé Södersvik, Rådmansö in Roslagen

- Modules in Skagershuset, Stockholm.

- Example of structure using cross laminated timber (CLT) and glulam

- Example of load-bearing wall unit using construction timber

- Example of connecting intermediate floor unit to load-bearing wall unit made from construction timber