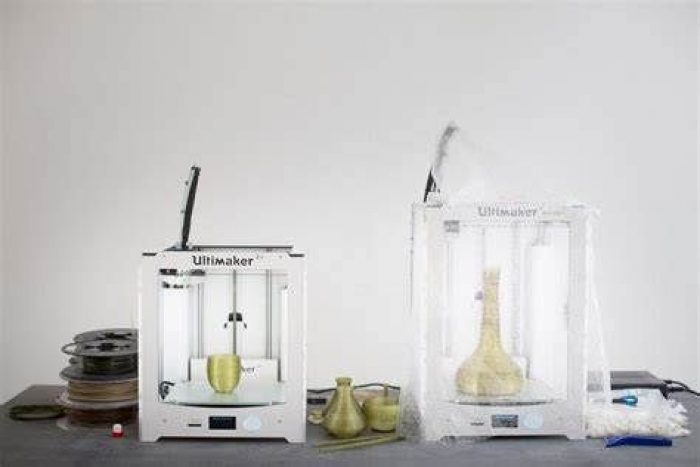

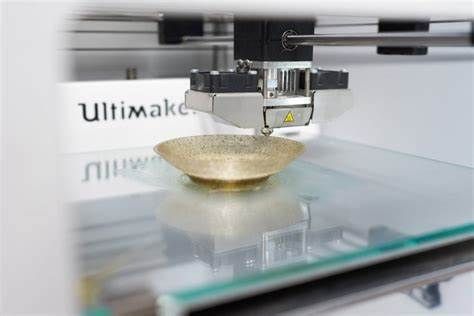

Eric Klarenbeek and Maartje Dros, the designers from the Netherlands, have succeeded in using algae to develop a new bioplastic, which is expected to offer a potential substitute for artificial plastic in 3D printing. The algae go through several processes to end up in a form that can be used as a material for 3D printing. The 3D printed items are eco-friendly and can be anything from baskets, bottles, and vases to seats and even whole facades.

Read more about the World-first 3D-printed Metal Bridge

The researchers have also developed biopolymers from starch, cocoa bean shells, and mycelium to be used for 3D printing. Currently, the duo aims to create a biopolymer-3D printer-network dubbed the 3D Bakery. Also, watch a video of a 3D Printer That is “Particularly Designed for Architects “Our idea is that in the future there will be a shop on every street corner where you can ‘bake’ organic raw materials, just like fresh bread,” Eric Klarenbeek explained. “You won’t have to go to remote industrial estates to buy furniture and products from multinational chains. 3D printing will be the new craft and decentralized economy.” Both Dros and Klarenbeek have graduated from the Design Academy of Eindhoven. 6 years ago, Klarenbeek has created the first 3D printed chair in the world to be created using mycelium.

The Dutch designers’ studio has been collaborating with Evocative, which is an American firm, to develop a line of commercial products based on mycelium, and they dubbed it “Krown”. The Do-It-Yourself kits have been a great hit as they allowed the consumer to print their own tables, lamps, as well as other decomposable items. “All around the world in recent decades, enormous amounts of fossil fuels have been extracted,” the researchers commented. “In this relatively brief period, a vast amount of carbon dioxide has been released into the atmosphere, with damaging consequences. It is therefore important that we clean the CO2 from the atmosphere as quickly as possible and this can be done by binding the carbon to biomass.” “Everything that surrounds us like our products, houses, and cars can be a form of CO2 binding,” the pair explained. “If we think in these terms, makers can bring about a revolution. It’s about thinking beyond the carbon footprint: instead of zero emissions we need ‘negative’ emissions.” “Algae is equally interesting for making biomass because it can quickly filter CO2 from the sea and the atmosphere,” they said. “The algae grow by absorbing the carbon and producing a starch that can be used as a raw material for bioplastics or binding agents. The waste product is oxygen, clean air.” “Our ambition is to provide all restaurants and catered events in the city with tableware,” they said. “We don’t want to grow into a large centralized organization,” added Klarenbeek, “We want to change the system so that people grow raw materials locally that they can use to produce things that comply with their needs.” The new technique is now on exhibition at Museum Boijmans Van Beuningen in Rotterdam. The display wraps up on 14th of January 2018.