Comprising numerous forward-looking and environmentally conscious technologies, the 50,000 m² complex designed by DADA Architectural Design + Planning for the 7th International Strawberry Symposium outside of Beijing, is an exercise in what good design can accomplish. The Symposium acts as a common forum for horticulturalists and producers of strawberry products to communicate amongst one another, develop collaborations and exchange ideas. It is an event set up around the idea of what can be done with a little ingenuity and thought to the future. As such, the winning submission for the scheme, currently under construction and meant to be completed in an extremely short 8 month period, is a corporeal embodiment of these principles. The most visible feature of the forms is their facade system, the first of its type in Chinese construction. The pre-cast, double curved panels are created from a fiberglass reinforced, composite concrete called SRC which, while enabling rapid construction, sacrifice little in quality and indeed carry a 50 year guarantee. Principles such as this, and the environmental considerations mentioned below, insure that the Symposium will only constitute a small fraction of the complex’ total lifespan.

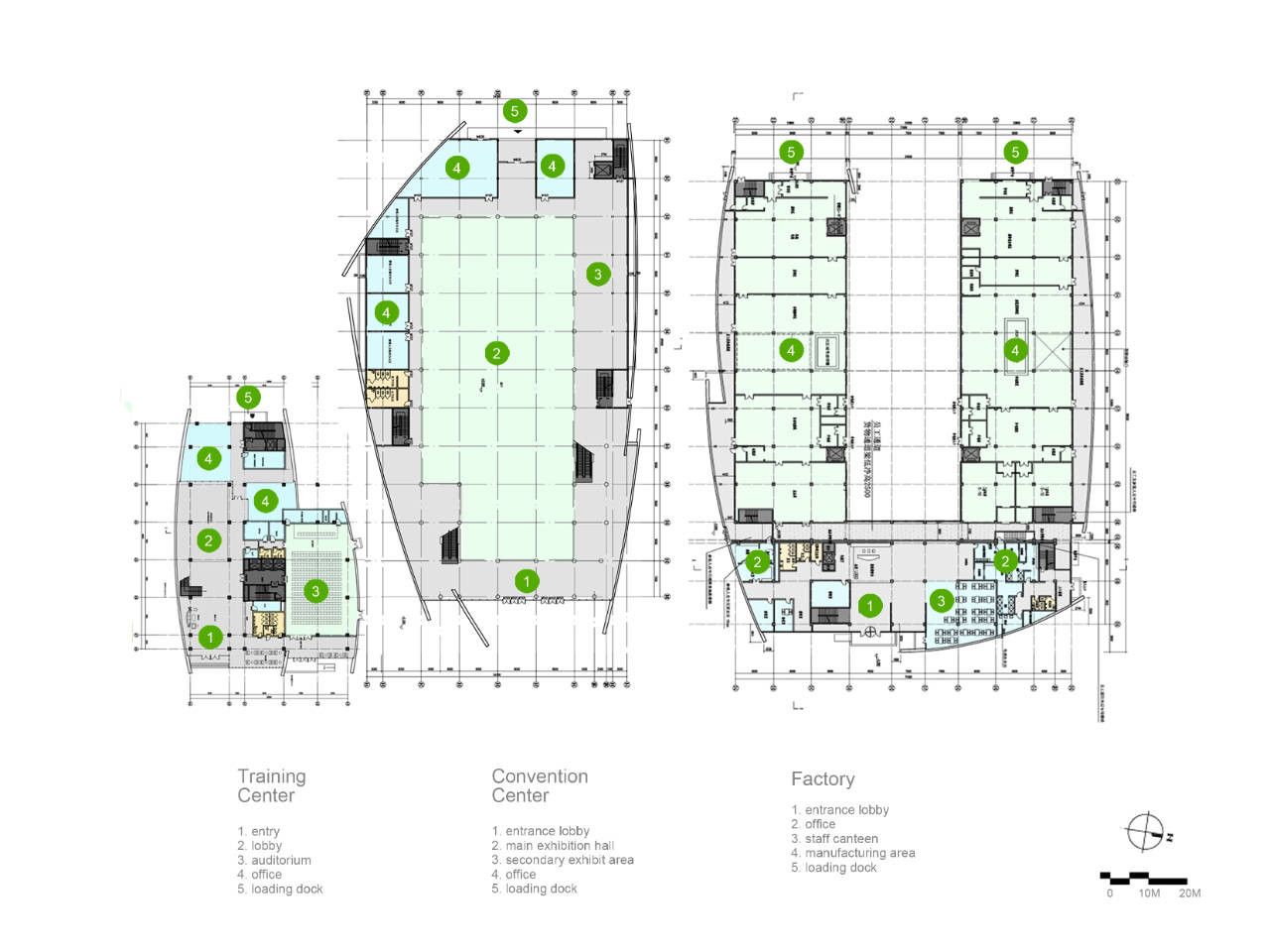

It is comprised of a Training Center, Convention Center, and Factory. The fundamental objectives driving the design were to fulfill the program while establishing an iconic presence towards the highway, and to infuse a unifying, engaging language upon the normally plain facades found on factory and convention center building types. We thus wrapped the boxy forms resulting from the functional layout with a series of white curvilinear shell structures that refer both to the organic form and texture of a strawberry, as well as traditional chinese screen patterns.

The massing is broken down via the use of multiple shells and canted glass curtainwalls with random frit patterns, allowing the scale of the architecture to become fluid and inviting. The shells tessellate into diagrids with progressively scaled windows, upon which white frits fade towards the center, obscuring the frames and further advancing the sense of abstraction. The design thus achieves a sense of scale and differentiation yet uses a language more akin to natural textures than building.

The shells are clad with SRC, a composite concrete panel using fiberglass reinforcement. This allowed for a low-cost, double-curved facade; a critical consideration given the modest budget. Moreover, panel prefabrication allowed us to meet the extremely rapid 8 month construction schedule without compromising geometric complexity. This project marks the first time that this technology has been utilized in an exterior application in China.

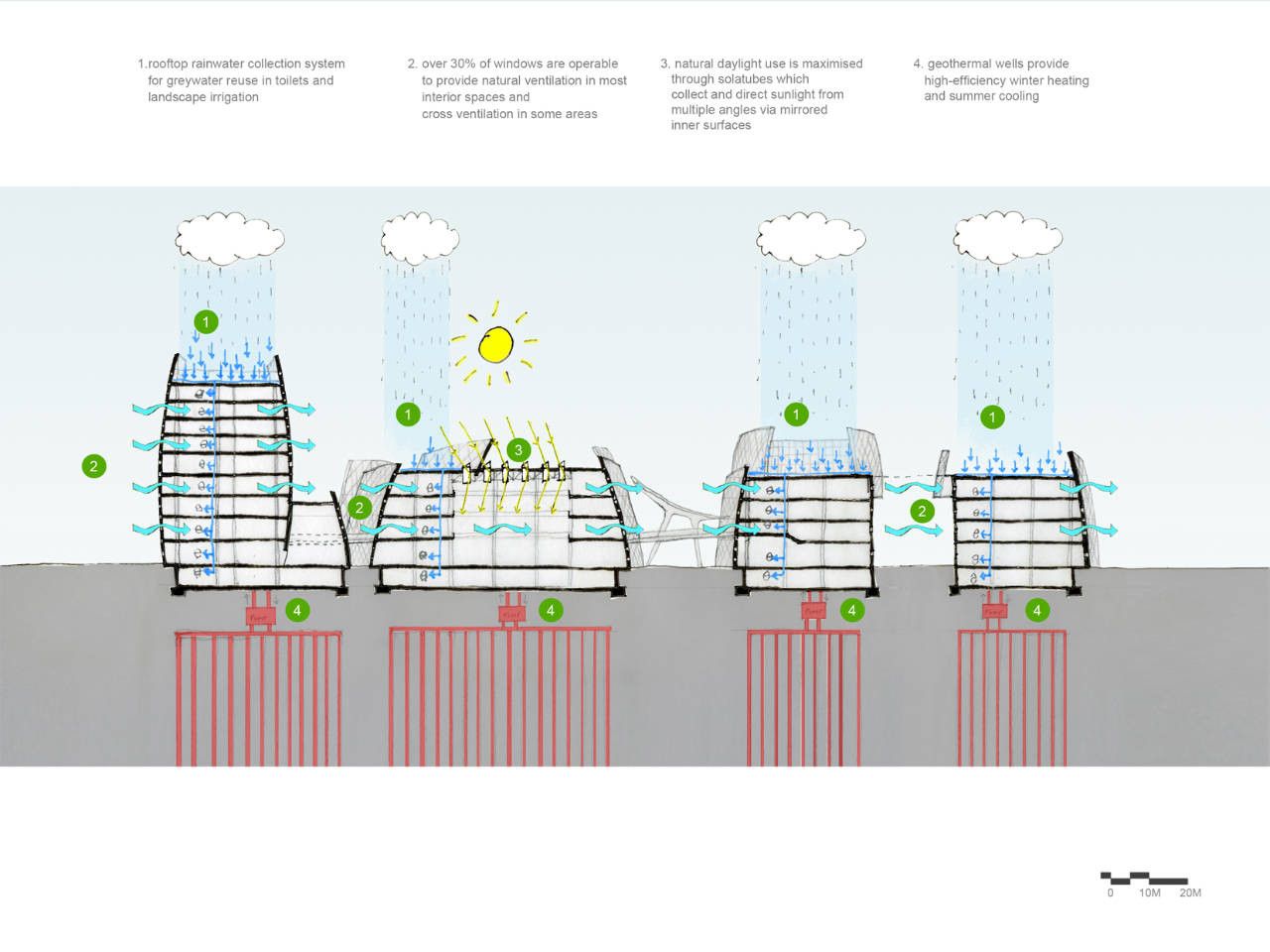

We set out to achieve a high degree of sustainability, using a combination of passive and active environmental control systems. Geothermal heating + cooling systems were installed. Additional green measures include a rainwater collection system for greywater recycling, selecting of materials with long lifespans ( -e.g. SRC carries a 50 year guarantee ), use of high-efficiency solatubes which pipe multidirectional sunlight like a fiber optic, and operable windows covering over 30% of faade areas to naturally ventilate most interior spaces. Green roofs were proposed but abandoned due to budget limitations. The project is designed to meet standards for the Three Green Star certification, the highest sustainable design rating in China.