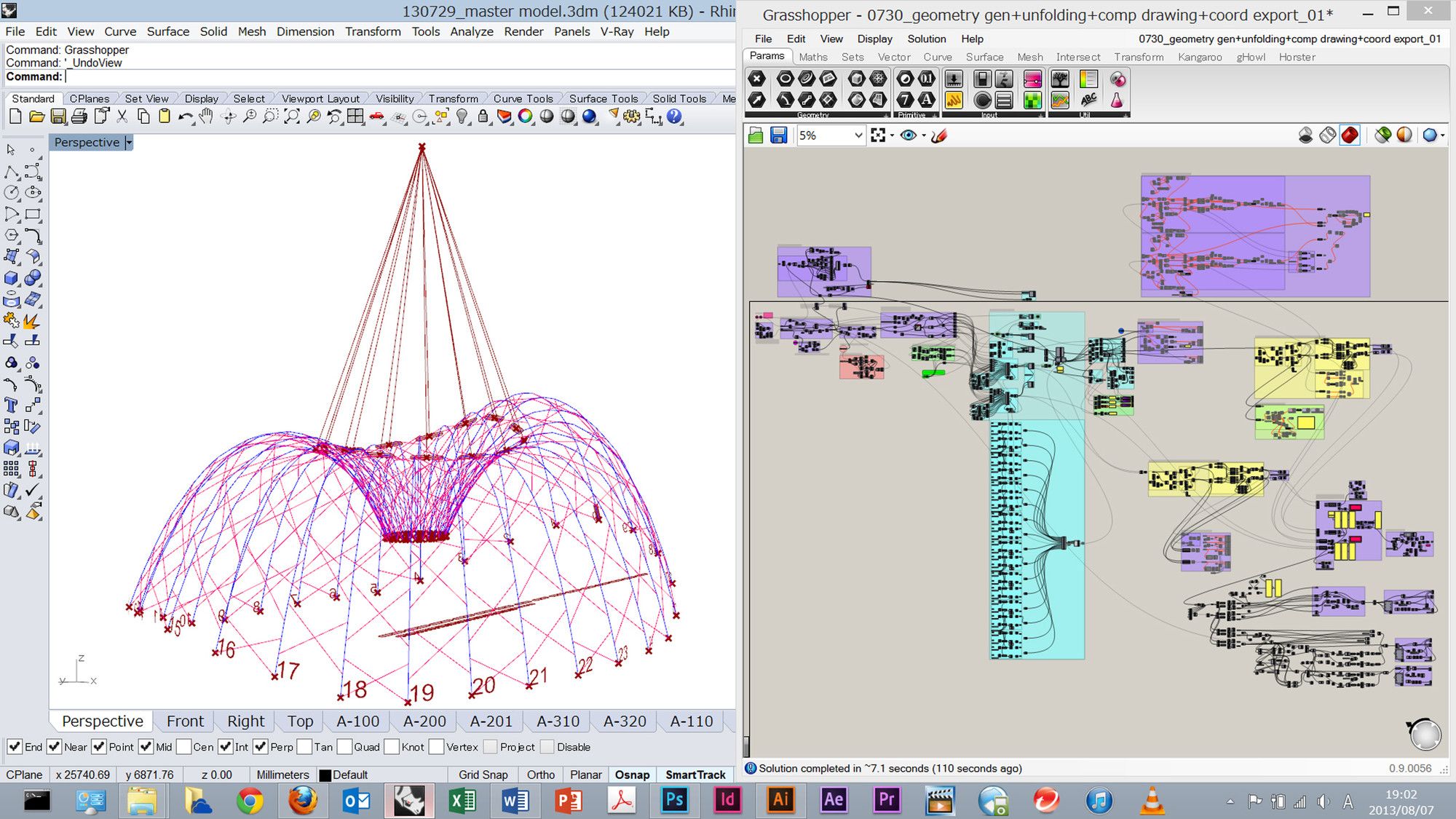

99 failures, the third pavilion project by the Digital Fabrication Laboratory of the University of Tokyo, Japan seeks to pay respect to the many failures before a success in the practice of architecture. Under the initiative of Kengo Kuma and Yuseke Obuchi, the pavilion expresses a highly immersive structural, material and spatially perceptual experience. The pavilion is the outcome of the lab’s investigation of structural and material behaviours in tensigrity models.

Tensigrity models are explorations of balancing tension and compression forces in sculptural objects.It dates back to the 1940’s and was coined by Buckminster Fuller who described it as synergetic explorations in structure and geometrical forms.

The tensigrity studies at the lab aim at investigating prototypical geometries to reconcile the contemporary issues of resource and material scarcity. The pavilion therefore serves as a conceptual and practical tool to generate a series of ideas rather than swiftly arrive at direct engineering solutions to these problems.

The tensigrity studies at the lab aim at investigating prototypical geometries to reconcile the contemporary issues of resource and material scarcity. The pavilion therefore serves as a conceptual and practical tool to generate a series of ideas rather than swiftly arrive at direct engineering solutions to these problems.

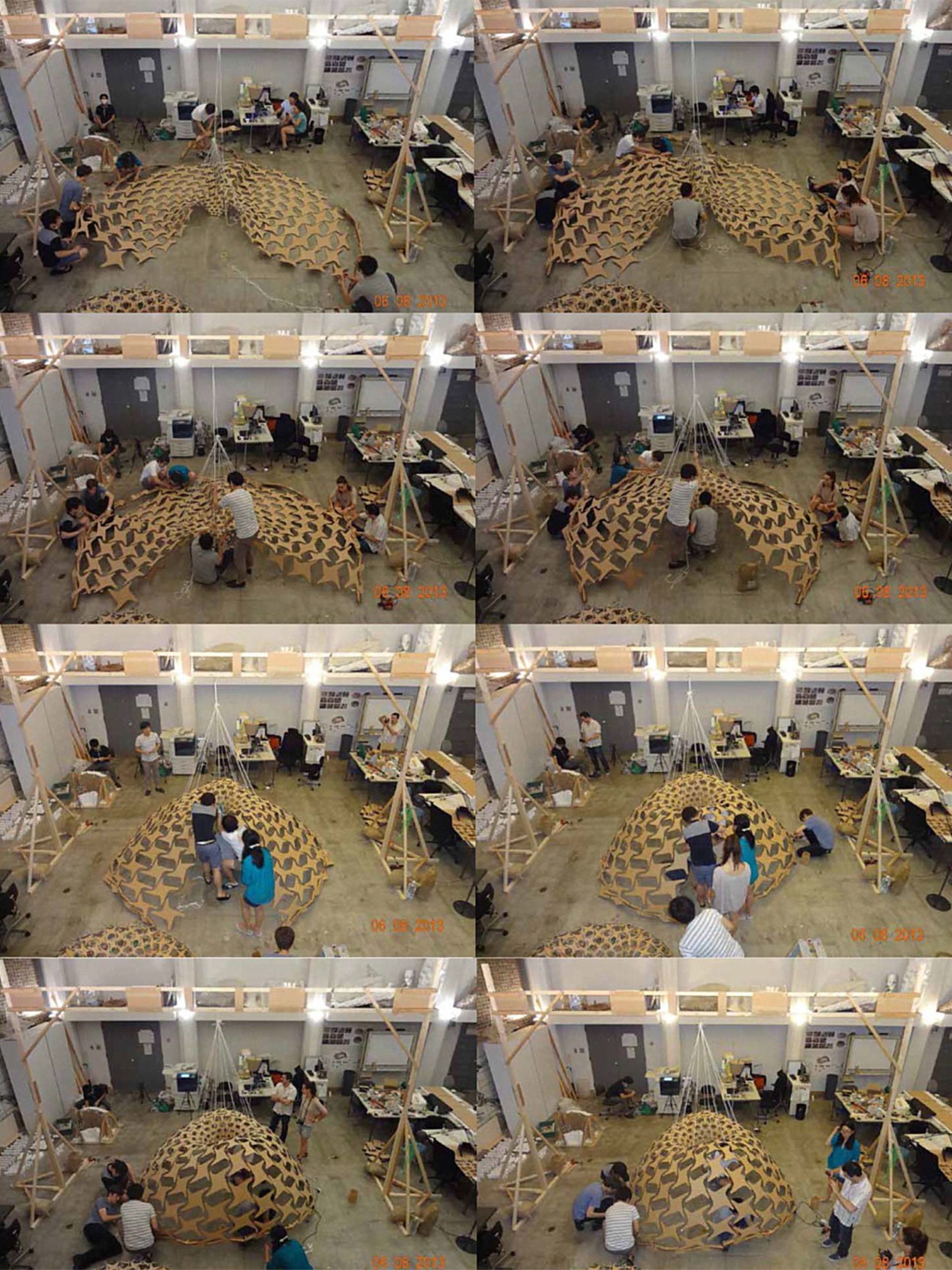

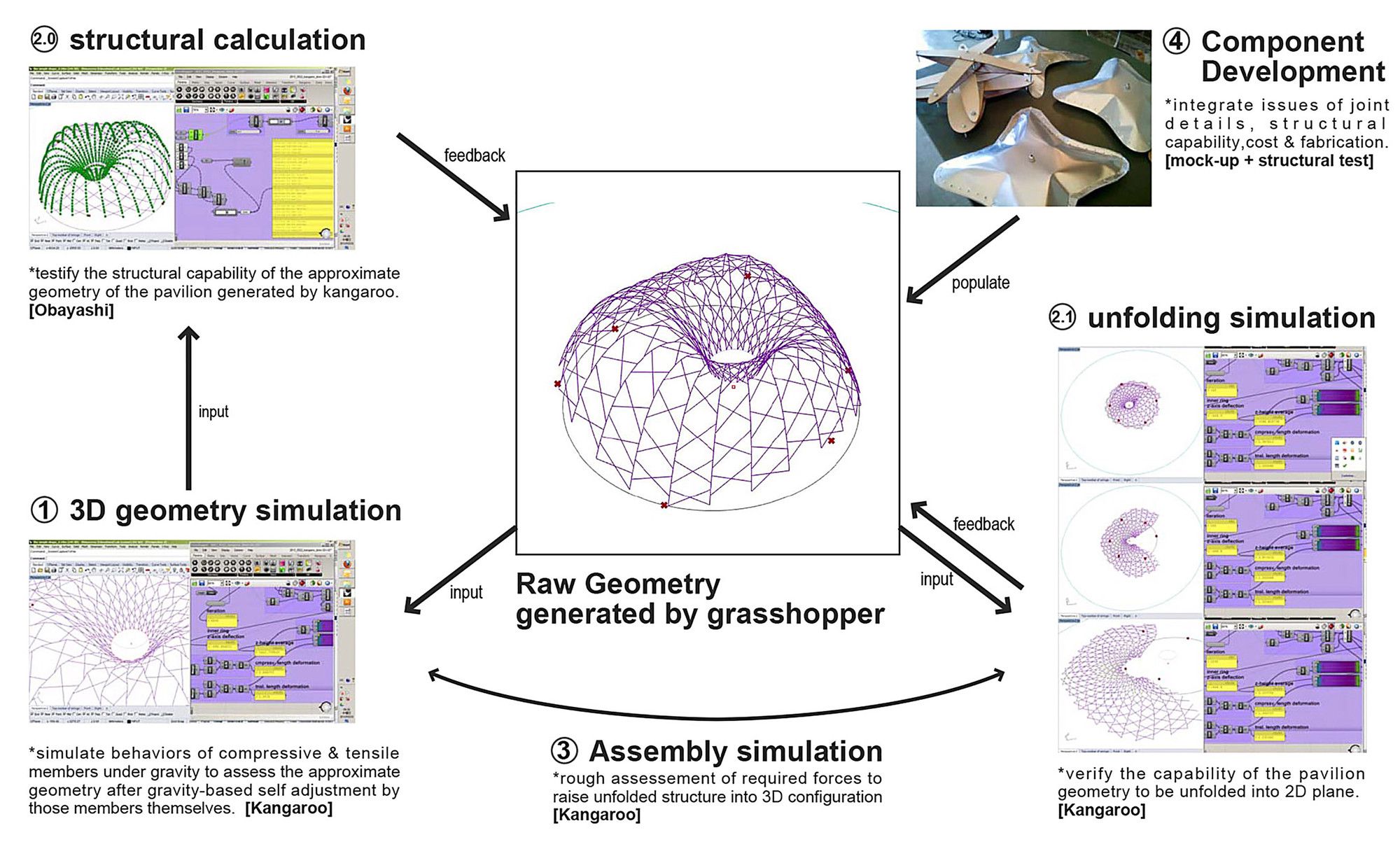

Obayashi Corporation, one of the project collaborators was invited to help choose a studio project for final realisation. The final choice according to studio assistant Toshiktasu Kiuchi was related to the “potential of the geometric form to be controlled and calibrated along the process of construction”.

Obayashi Corporation, one of the project collaborators was invited to help choose a studio project for final realisation. The final choice according to studio assistant Toshiktasu Kiuchi was related to the “potential of the geometric form to be controlled and calibrated along the process of construction”.

99 Failures Pavilion

99 Failures Pavilion

Project: The University of Tokyo, Digital Fabrication Lab Pavilion 2013

The University of Tokyo teaching staff: Yusuke Obuchi, Toshikatsu Kiuchi, So Sugita, Hironori Yoshida

The University of Tokyo students: Christopher Sjorberg, Yeonsang Shin, Miguel Puig, Zhang Ye, Ana Luisa Soares, Ma Sushuang, Tong Shan, Andrea Trajkovska, Quangtuan Ta, Wei Wang, Anders Rod, Benjamin Berwick, Qiaomu Jin, Fawad Osman, Yanli Xiong, Andrea Bagniewski, Kevin Clement, Ornchuma Saraya, Minjie Xu

Obayashi Corporation: Tomoo Yamamoto, Kenichi Misu, Gendai Ono, Yasuo Ichii, Keisuke Fujiwara, Shunsuke Niwa, Tatsuji Kimura, Masaru Emura, Taiki Byakuno, Takahide Okamoto

Structural engineer: Jun Sato

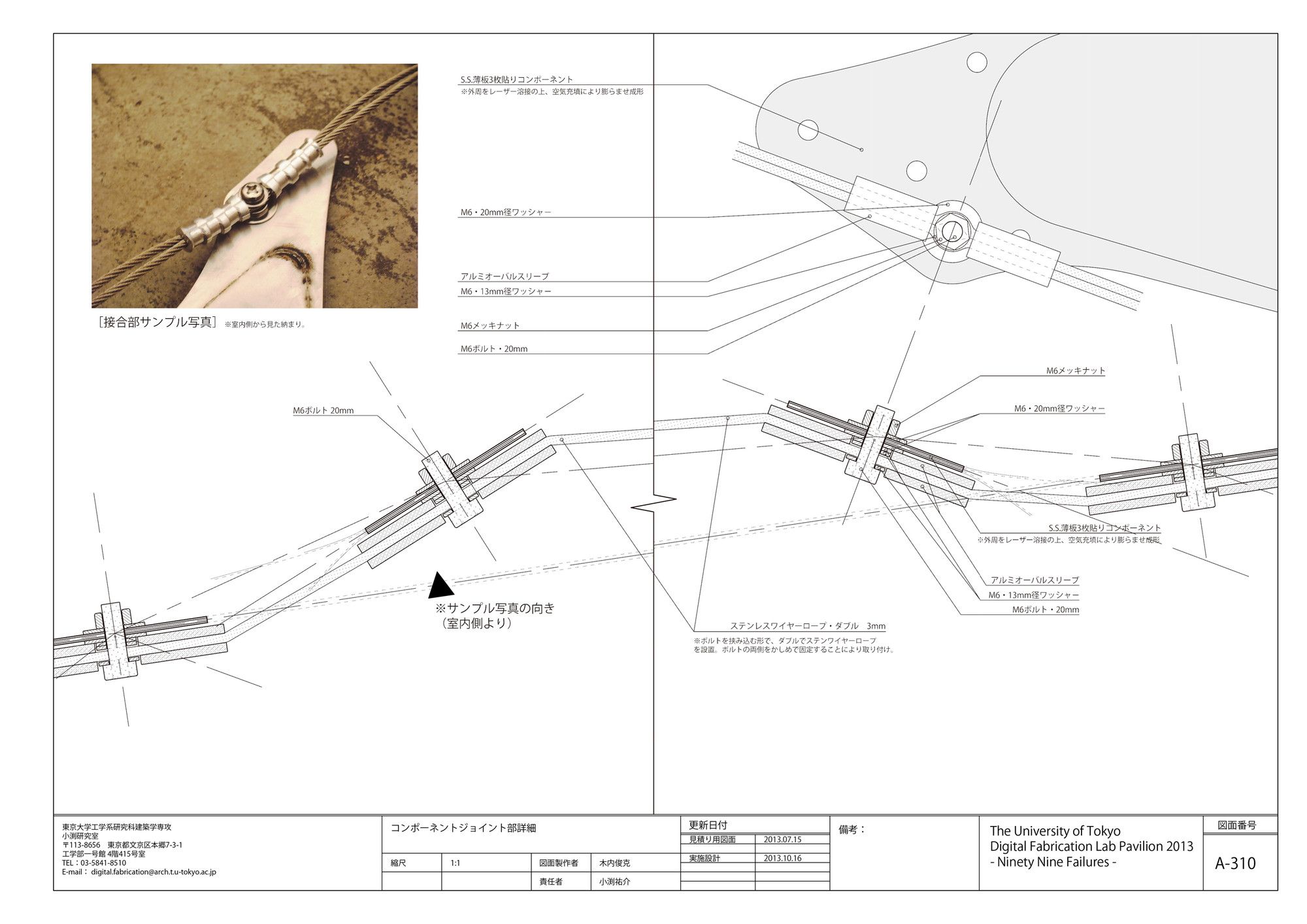

Fabrication of components: Tsukasa Takenaka (AnS Studio)

Construction: Multibuilder

Fabrication: Togari Kogyo

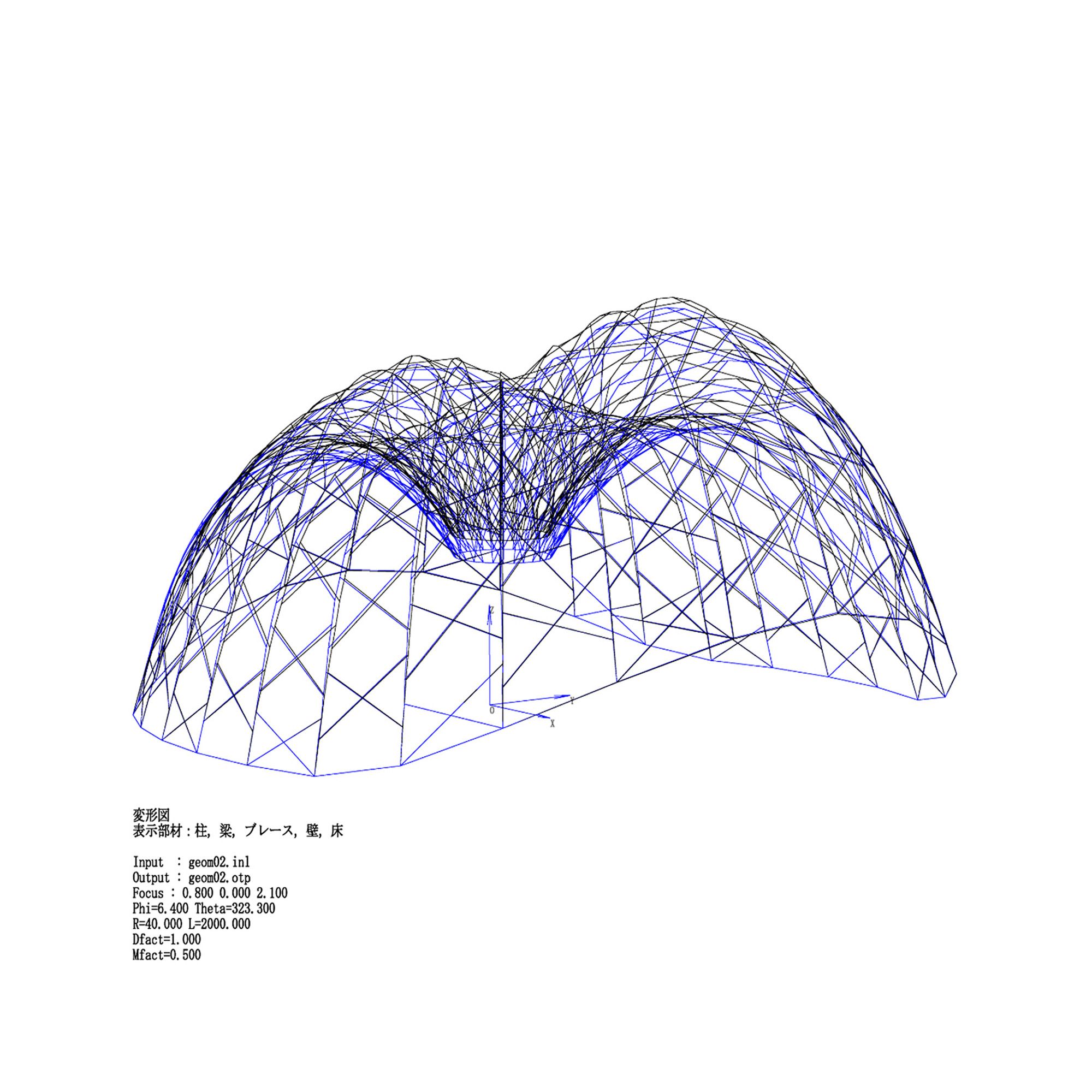

Structure: Freeform Surface Tensegrity Structure

Materials:

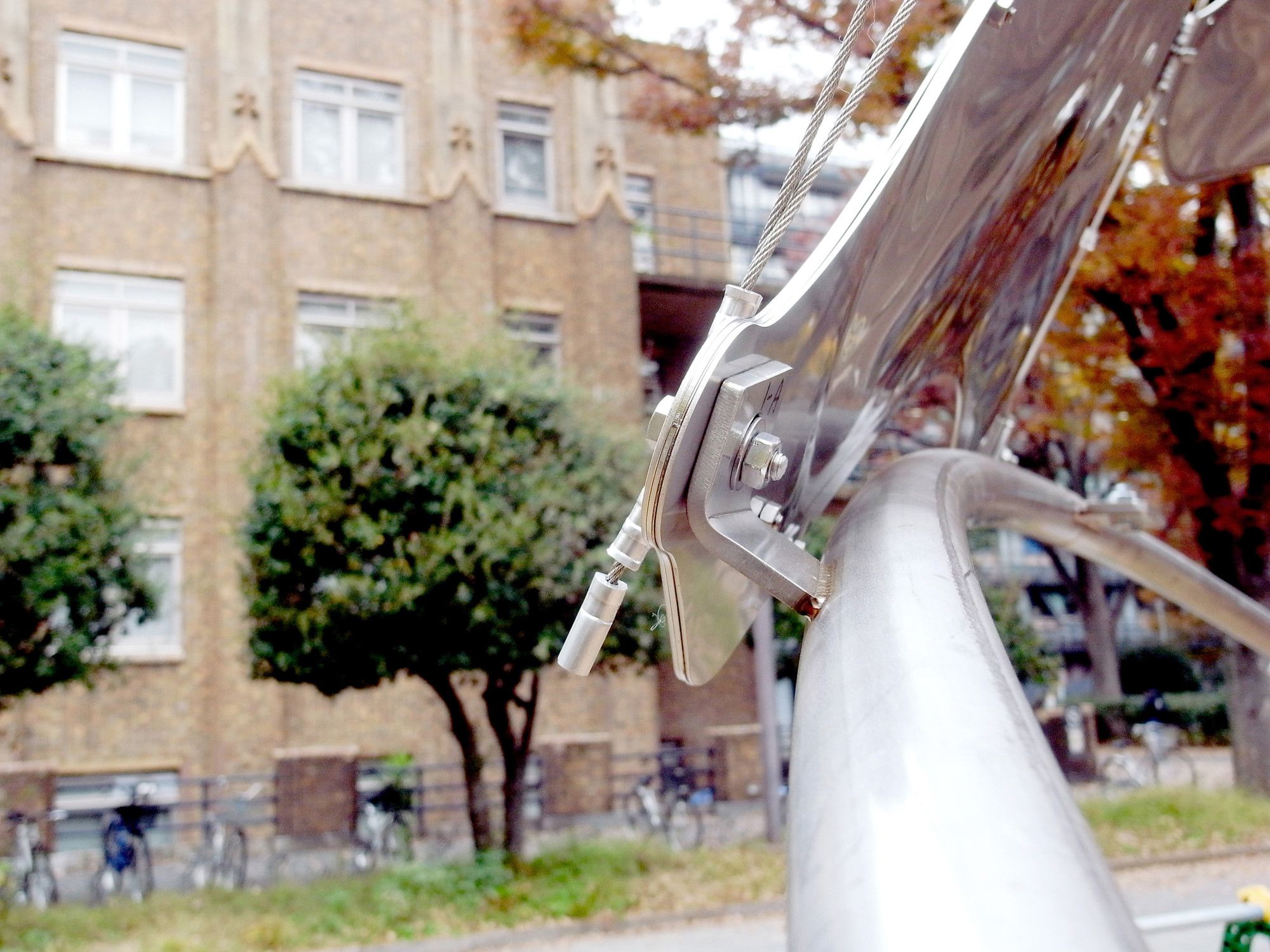

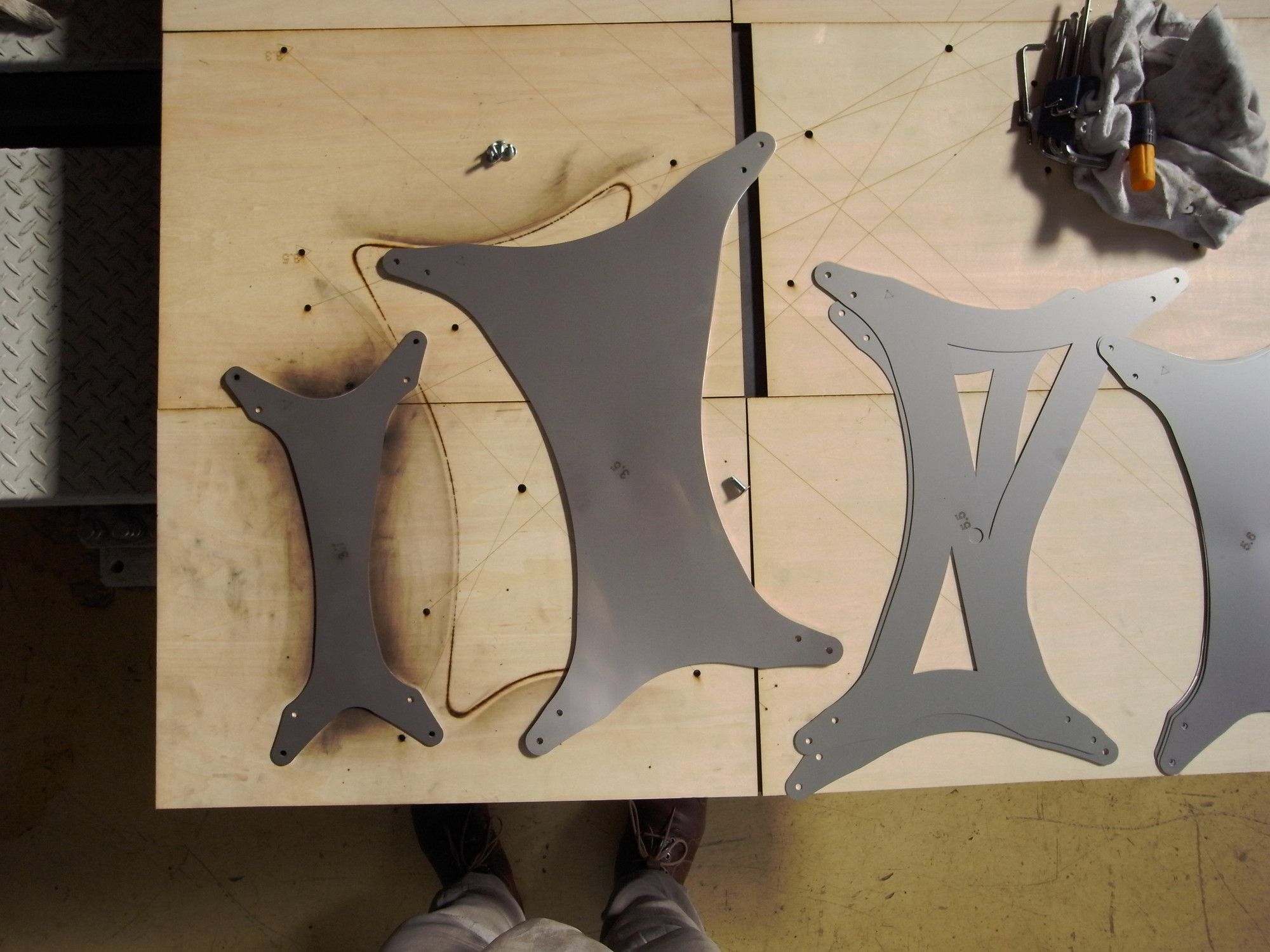

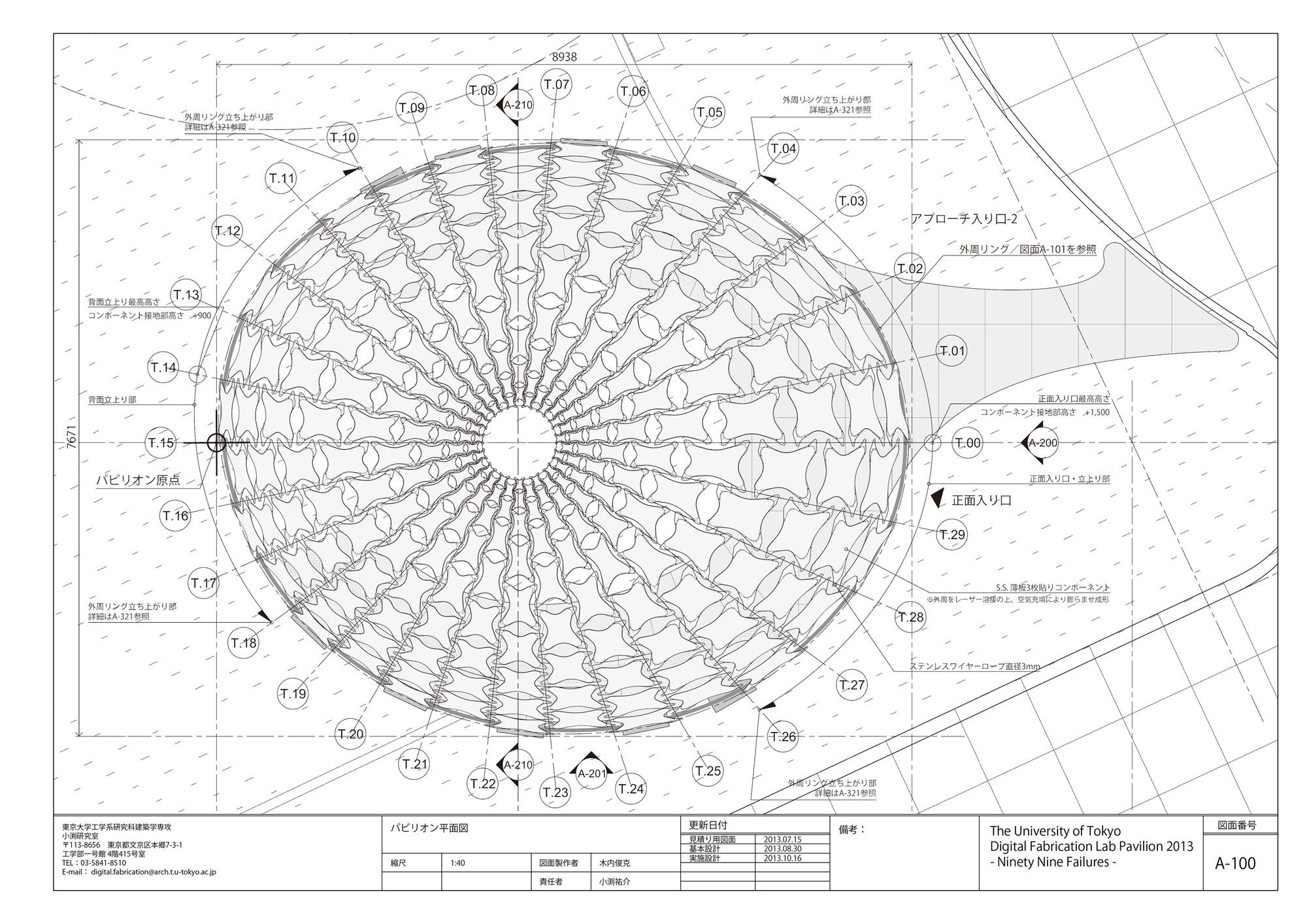

Compressive components: stainless steel plates with 0.5 mm / 0.8 mm / 1.2 mm / 1.5 mm thickness

Tension cables: stainless steel cables in 3 mm diameter

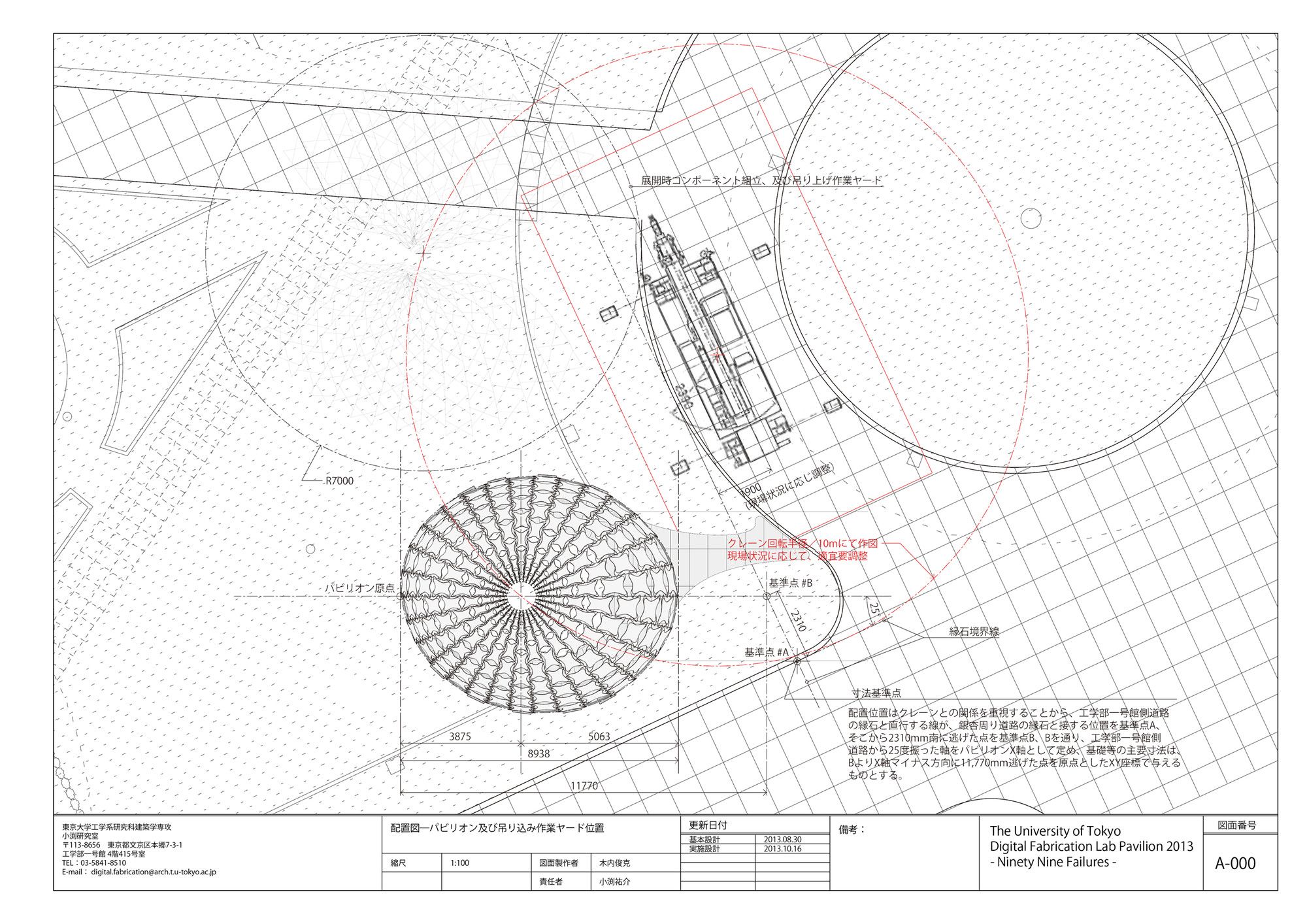

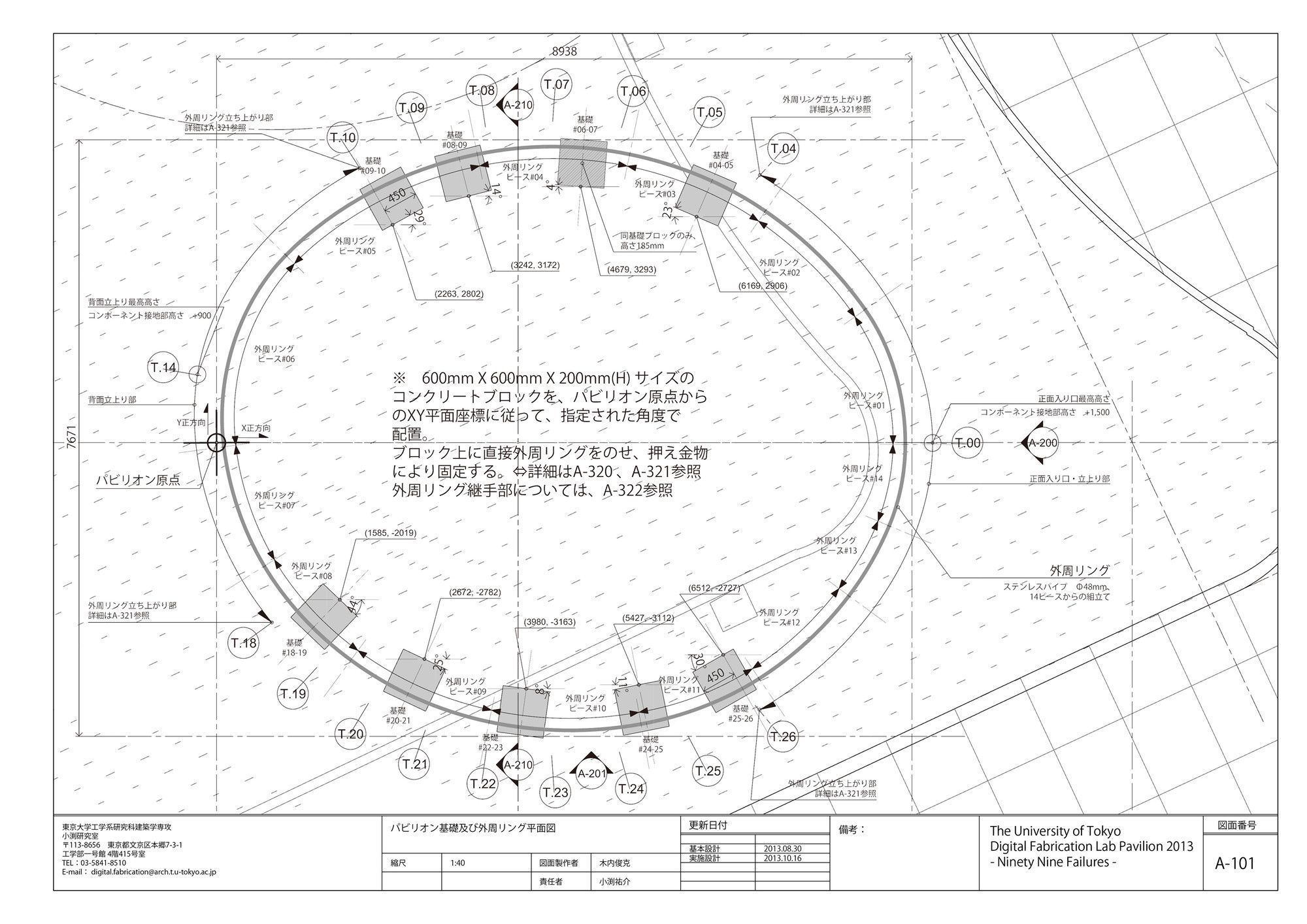

Base ring: stainless steel pipe in 48mm diameter

Foundation: precast concrete blocks

Furniture: painted plywood

Weight: 1.5 t (upper structure in stainless steel), 1 t (concrete foundation)

Design Phase: October 2012 – March 2013

Design development, fabrication & construction: April – November 2013

Completion date: 24 November 2013

Photography by © Hayato Wakabayashi

Photography by © Hayato Wakabayashi

Photography by © Hayato Wakabayashi

Photography by © Hayato Wakabayashi

Photography by © Hayato Wakabayashi

Photography by © Hayato Wakabayashi

Photography by © Hayato Wakabayashi

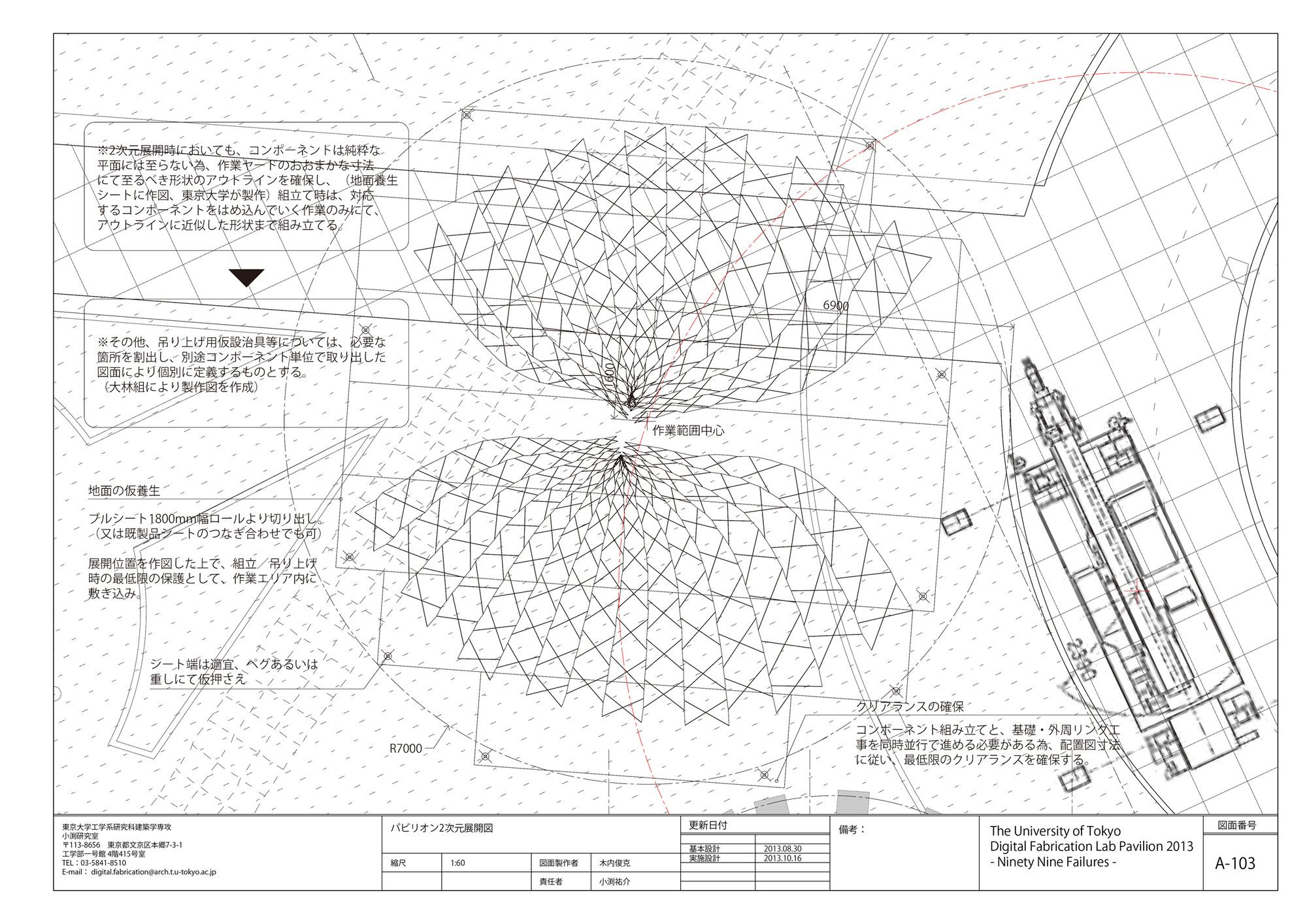

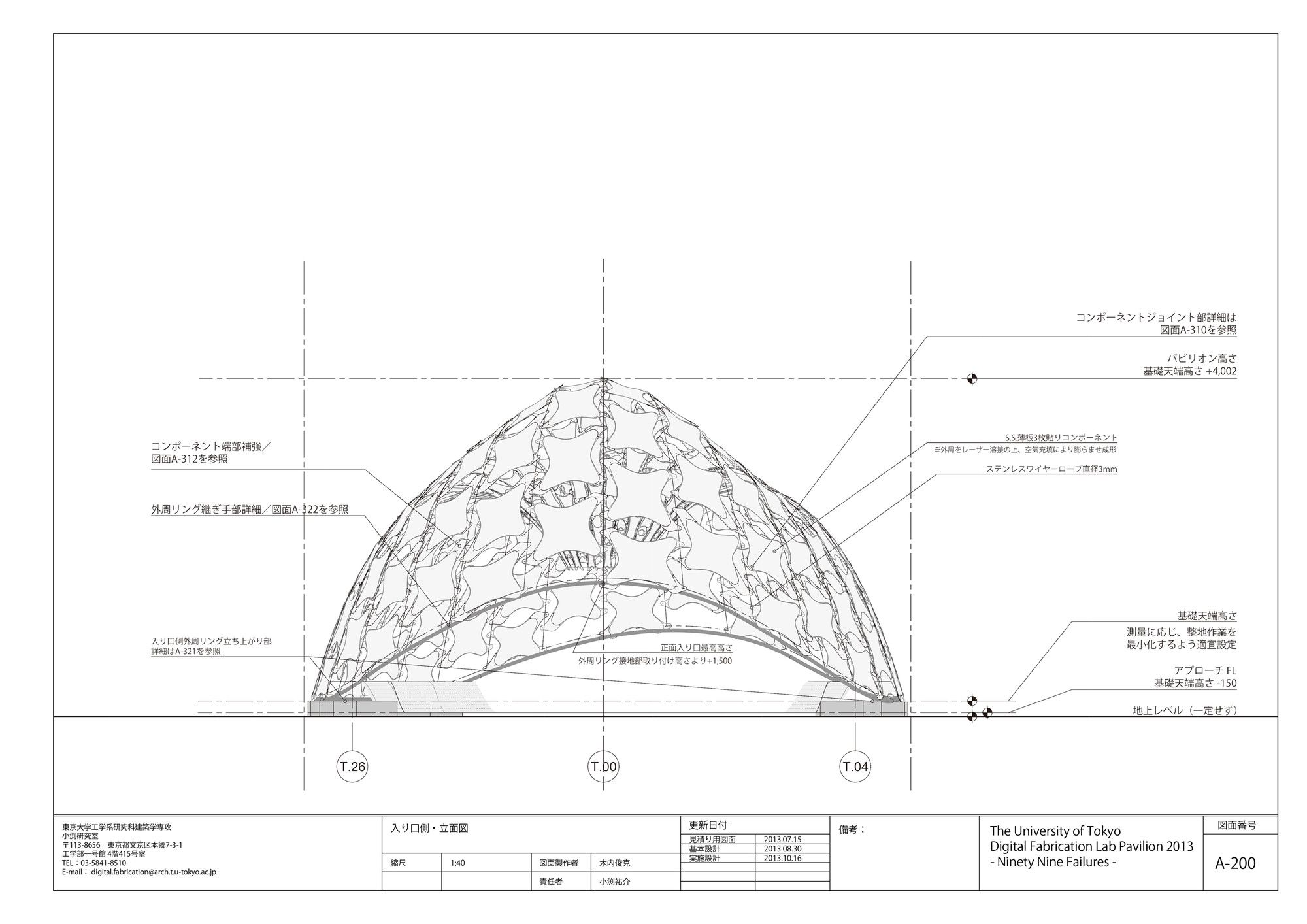

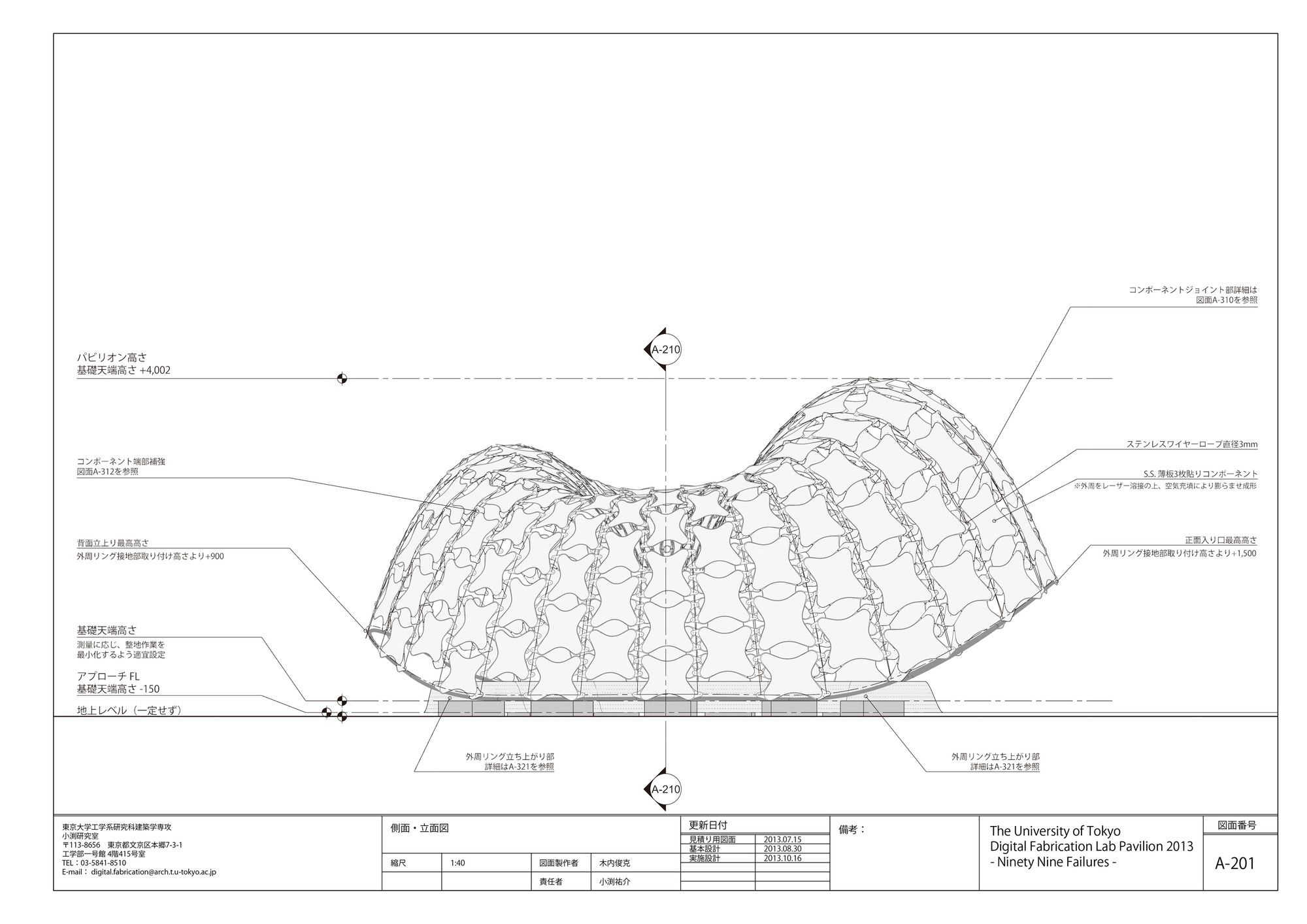

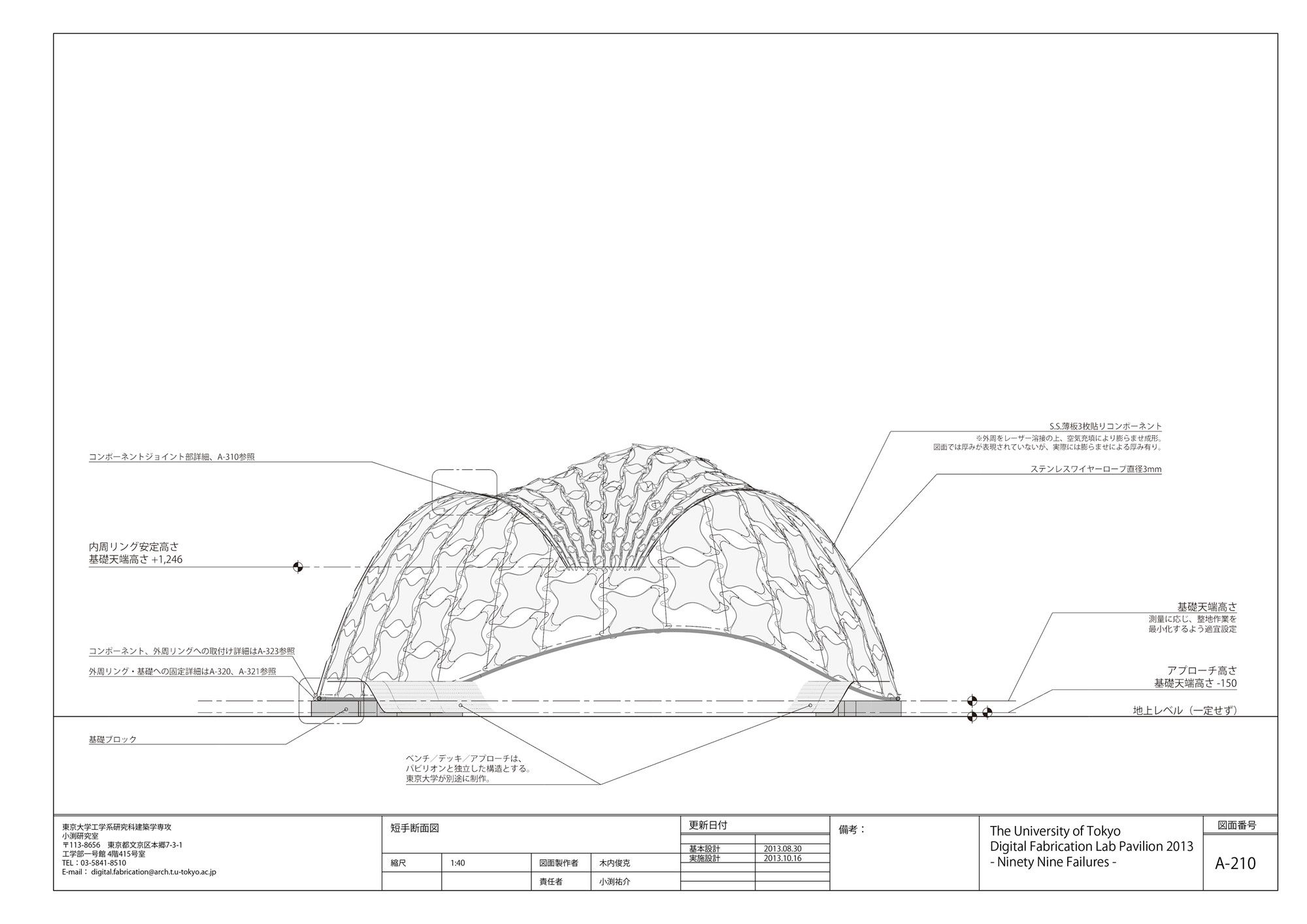

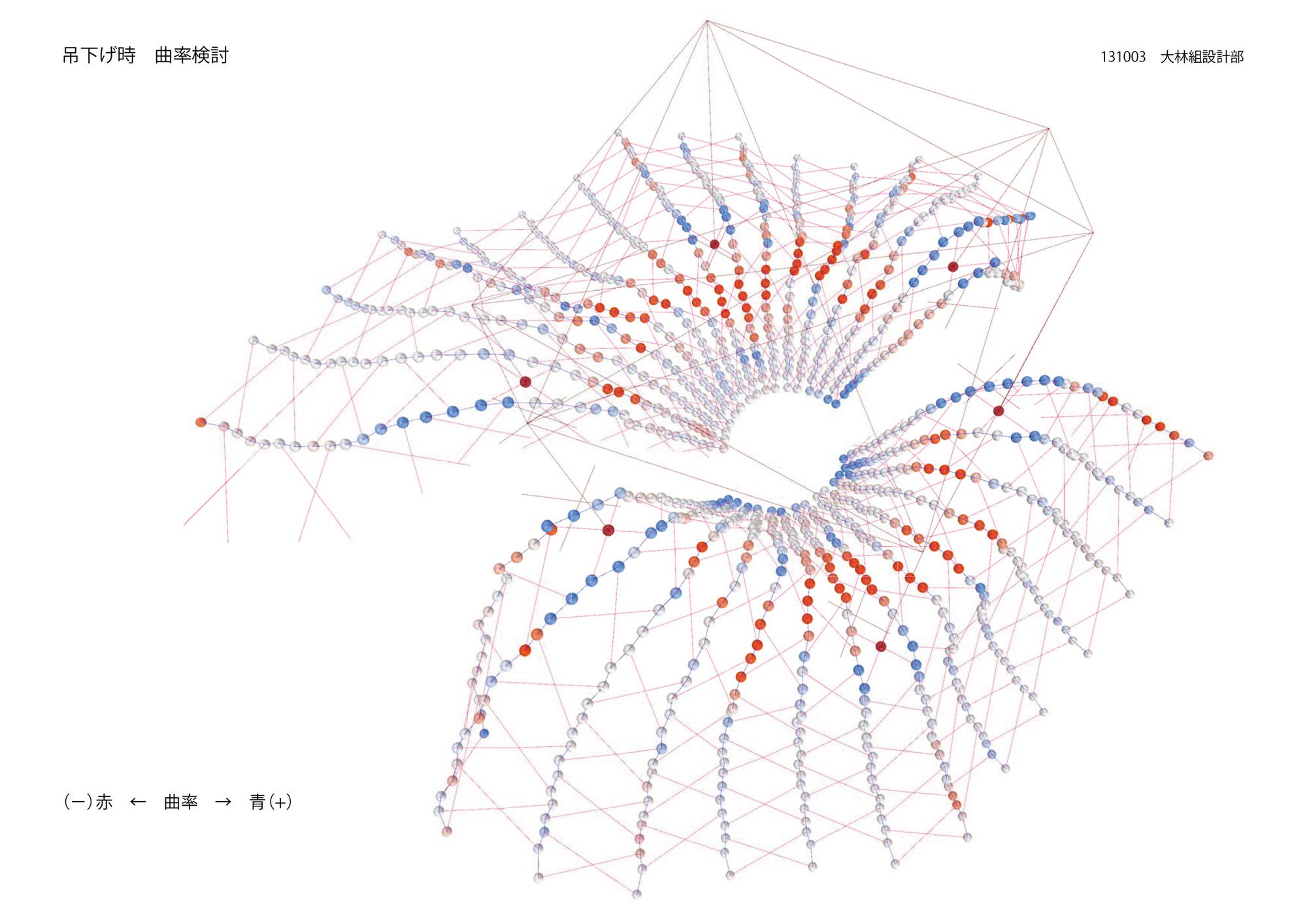

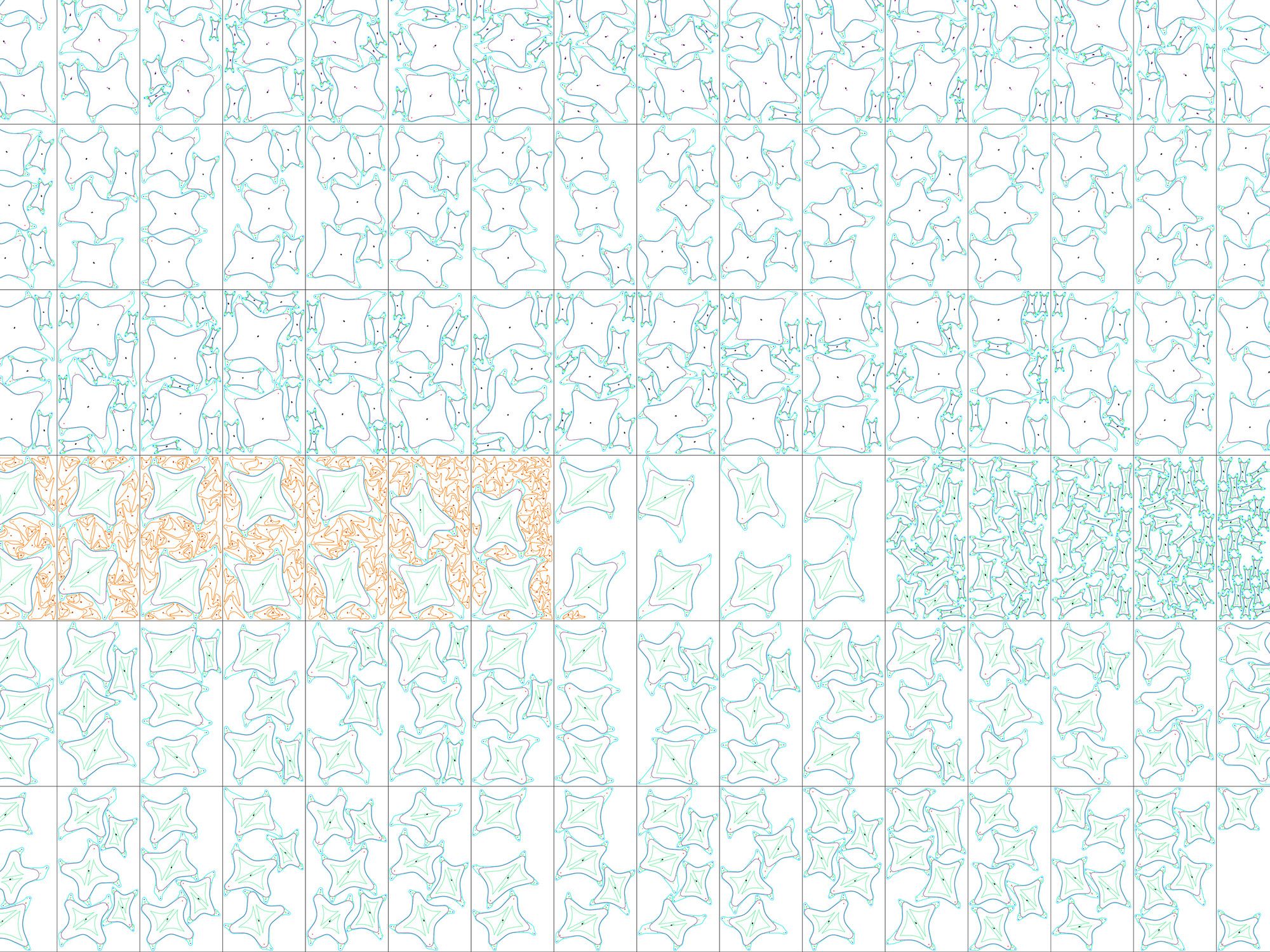

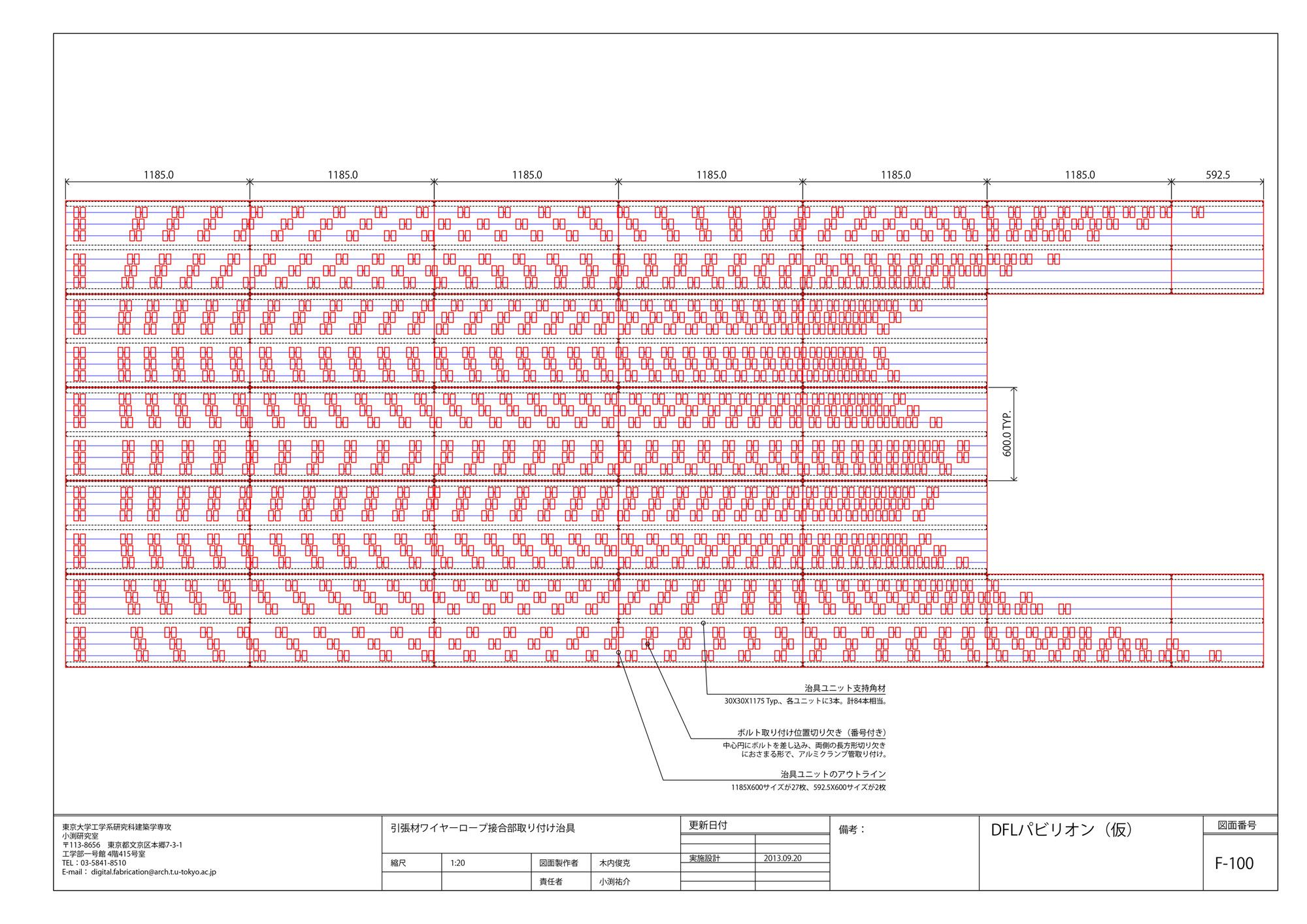

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Exif_JPEG_PICTURECourtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Courtesy of © The University of Tokyo Digital Fabrication Lab

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail

Detail