What Happens When Architects Design Desserts

The Ukranian pastry chef Dinara Kasko has found in pastry a field in which she can combine baking with geometric figures and architectural designs. Kasko isn’t your average baker, she’s also an architectural designer who’s using her skills to come up with cake designs that’ll numb your mind—quite literally. Kasko has been experimenting with geometrical and architectural concepts to create pastries that are unlike anything you’ve ever seen before. She told SoGood Magazine that “A beautiful cake, as well as a beautiful building, needs preliminary design. It’s necessary to work with the form, volume, composition, proportion, color and texture correctly”

“As for me, I’m a creative person. I have always been interested in art. So I went to the University of Architecture and Design and worked as an architect-designer and a 3D visualizer for several years. I also had a lot of experience in photography and just a few years ago finally discovered baking for myself. I studied patisserie at home in my small kitchen and attended courses with famous professional pastry chefs from time to time. I carry out some new experiment every single day and patisserie has become my biggest interest and my passion.” Dinara spoke to Sogood magazine

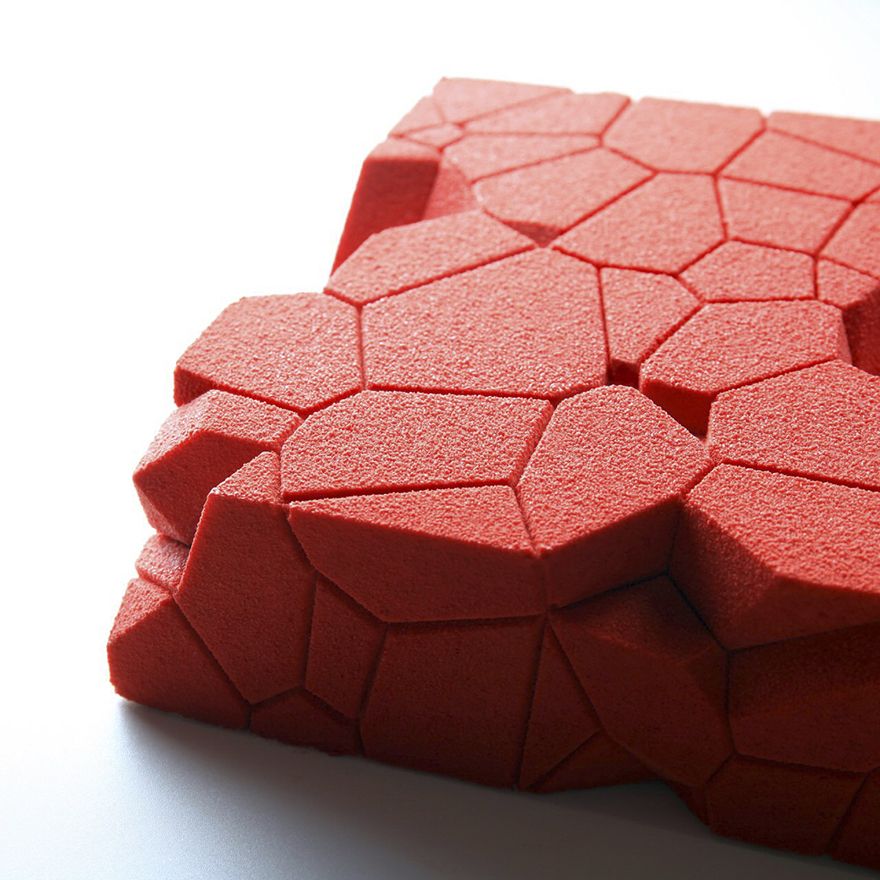

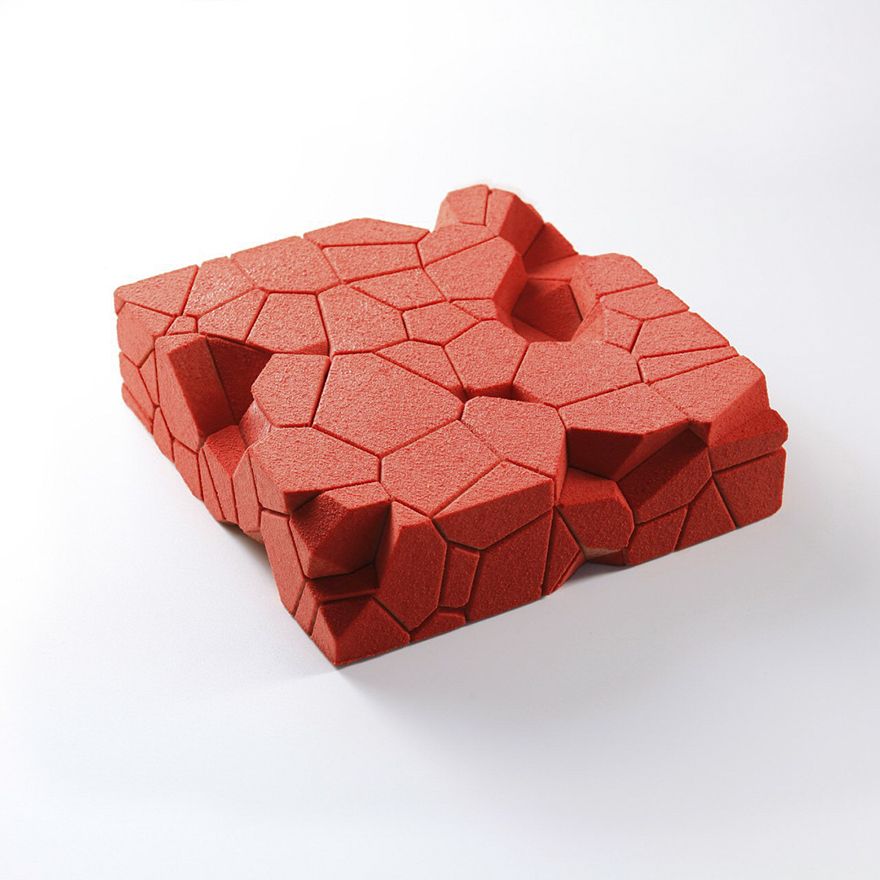

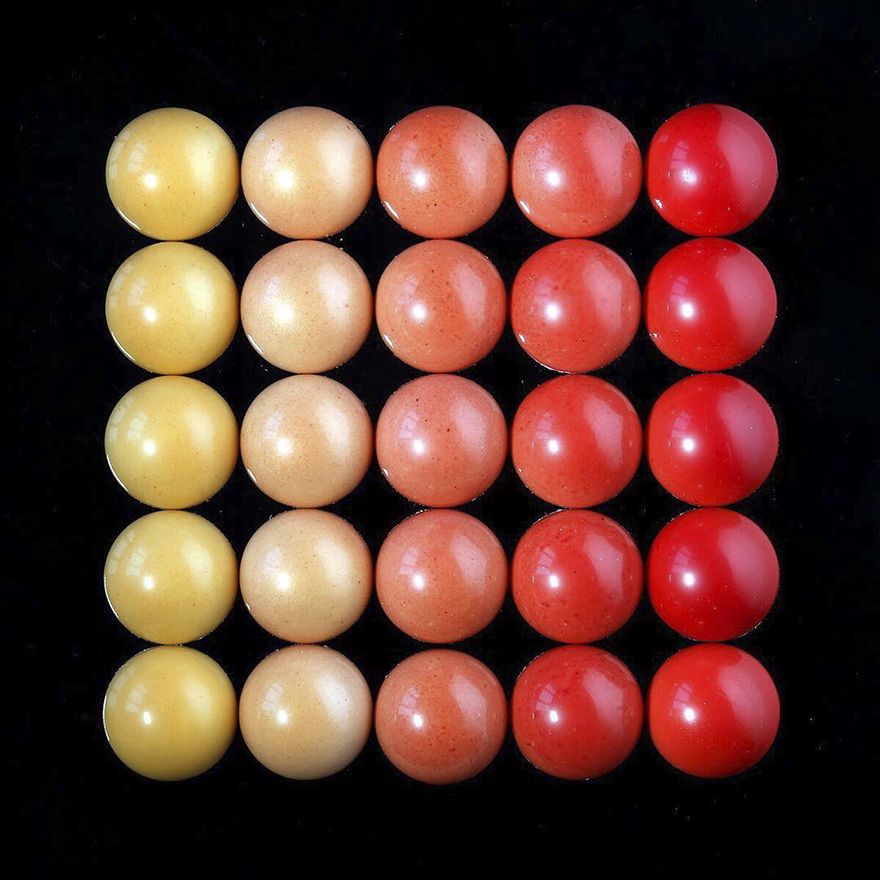

Kasko is experimenting constantly with new techniques. She thinks that the object’s creation begins from design development, and you can see mathematical concepts like the Voronoi diagram come to life in her creations. She balances form, color, architecture, proportion, and texture to create cakes that are like edible versions of The Guggenheim in design and creativity.

Each object’s creation begins from design development. There are few stages: inspiration, shape, and my own style. At the beginning the irrational is born – the very idea, then through shaping, I rationalize my object, and in the last stage I assign my own style to the object, which eventually generates a particular concept.

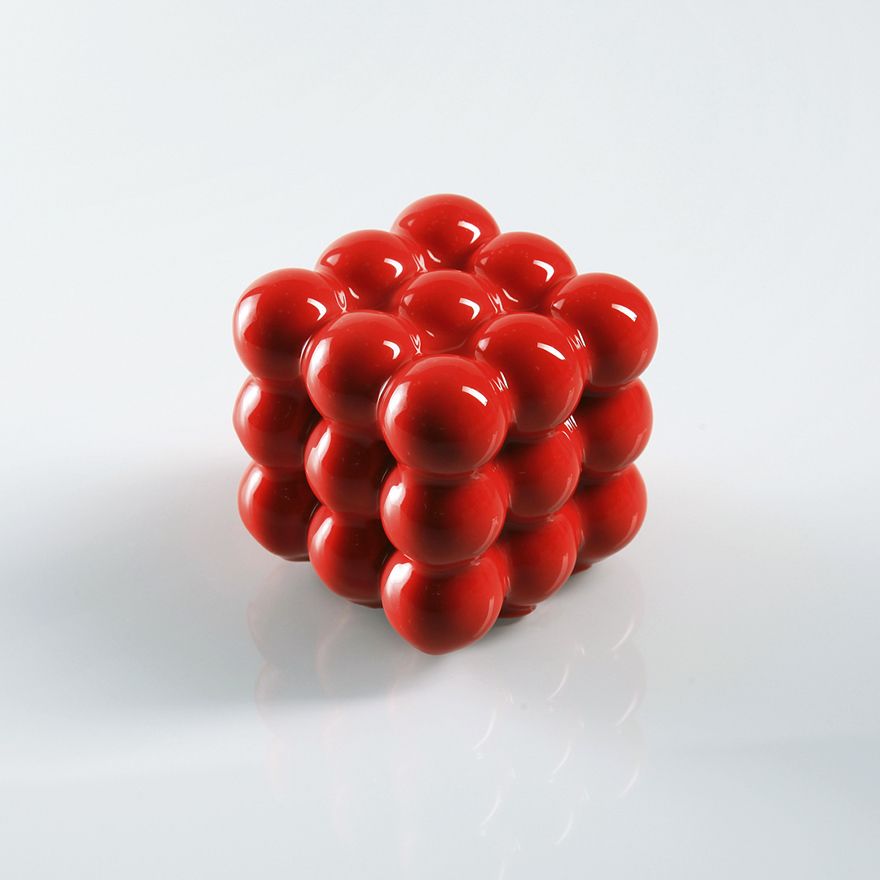

When my future creation’s form is complete, I begin to implement it. In terms of my own moulds, first of all I make them on my computer. Even in this stage I can create the whole scale, proportions, I can vary the color, texture, choose decorations.

The next step is to print the 3D master model on the printer and its post-processing. Finally we cast the silicone mold.

Presently I have started to work with the silicone molds producers – Silikomart liked some of my molds, and decided to put them into mass production. The Bubbles mold will be available for sale in September.