Exploring building materials that have a low environmental impact has been concerning contemporary architects and professionals of the construction field, especially since various global crises are escalating.

Hempcrete is one that successfully passed as an alternative building material. It performs in an environmentally friendly manner through its whole lifecycle—in its growing plant phase, hemp absorbs carbon dioxide; when used in construction, it’s an effective insulator and a non-toxic material; and after demolition, it can be recycled and reused. Hempcrete is an alternative building material with promising advantages.

In Arch2O, we discussed the potential of hempcrete as a sustainable building material. Moreover, with little additions, some architects believe it can be strong enough to build a house that twists and twines! Keep reading to explore examples of architecture built using hempcrete.

Twine House by Antony Gibbon – Image is Courtesy of Antony Gibbon Designs

What are the benefits of hempcrete?

- It is a carbon-negative material: the carbon hemp absorbs as a plant makes up for the carbon emitted during the processing phase of hempcrete.

- It is fire resistant and creates safe buildings.

- Hempcrete needs no added chemicals, hence it creates healthy indoors.

- It is an effective thermal insulator and performs well with temperature fluctuations.

- Hempcrete absorbs moisture during times of high relative humidity and releases it when the relative humidity drops.

- It is resistant to pests and other termites.

- In the processing phase, hempcrete requires less water than traditional cement.

- It takes decades to fully cure, so its strength and feature improve over time.

Pierre Chevet Sports Center by Lemoal Lemoal – Photography is by Elodie Dupuy

Is Hempcrete Stronger Than Concrete?

Hempcrete has a compressive strength of around 1/20 and only 15% density that of concrete. So, no, hempcrete is not stronger than concrete and hence must be used with the support of a load-bearing structural system of another material. However, the good news is because of the low density, hempcrete is resistant to cracking under movement, which makes it perfect for areas prone to earthquakes.

List of 5 Projects Using Hempcrete

-

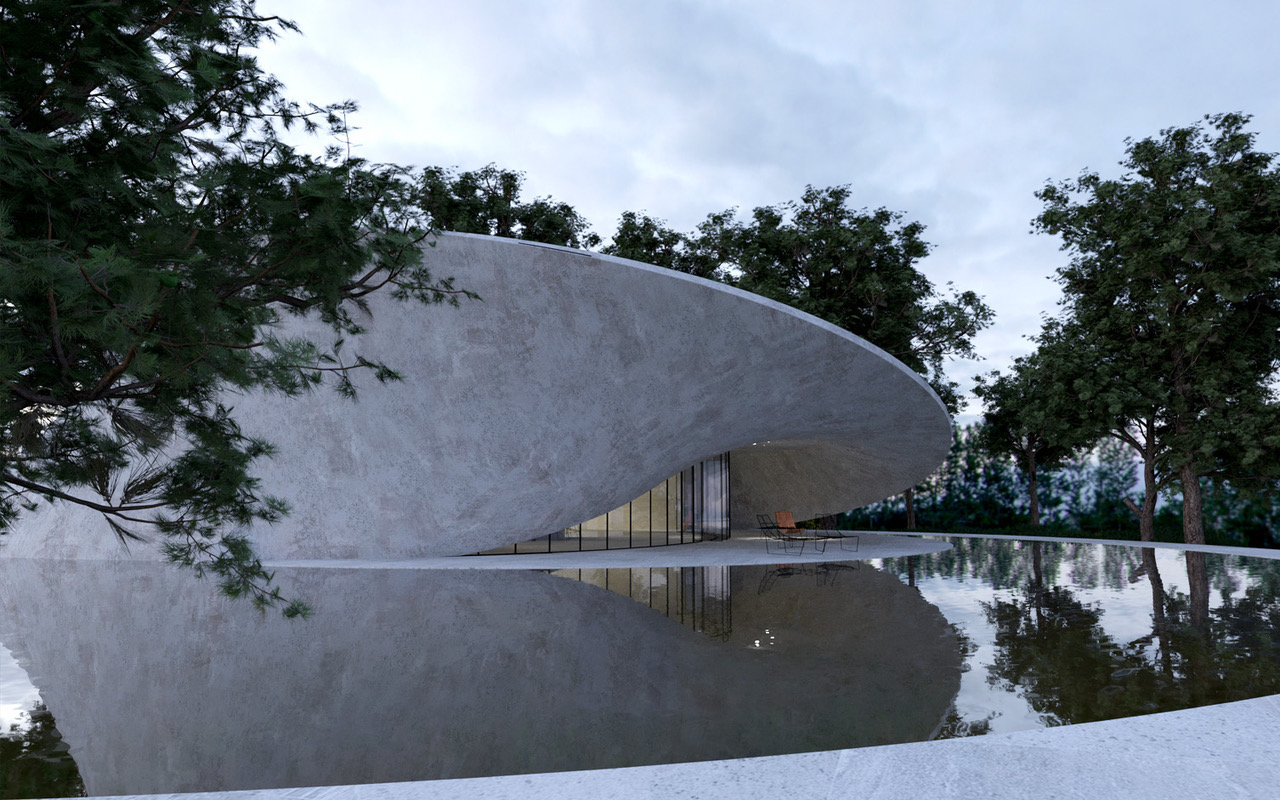

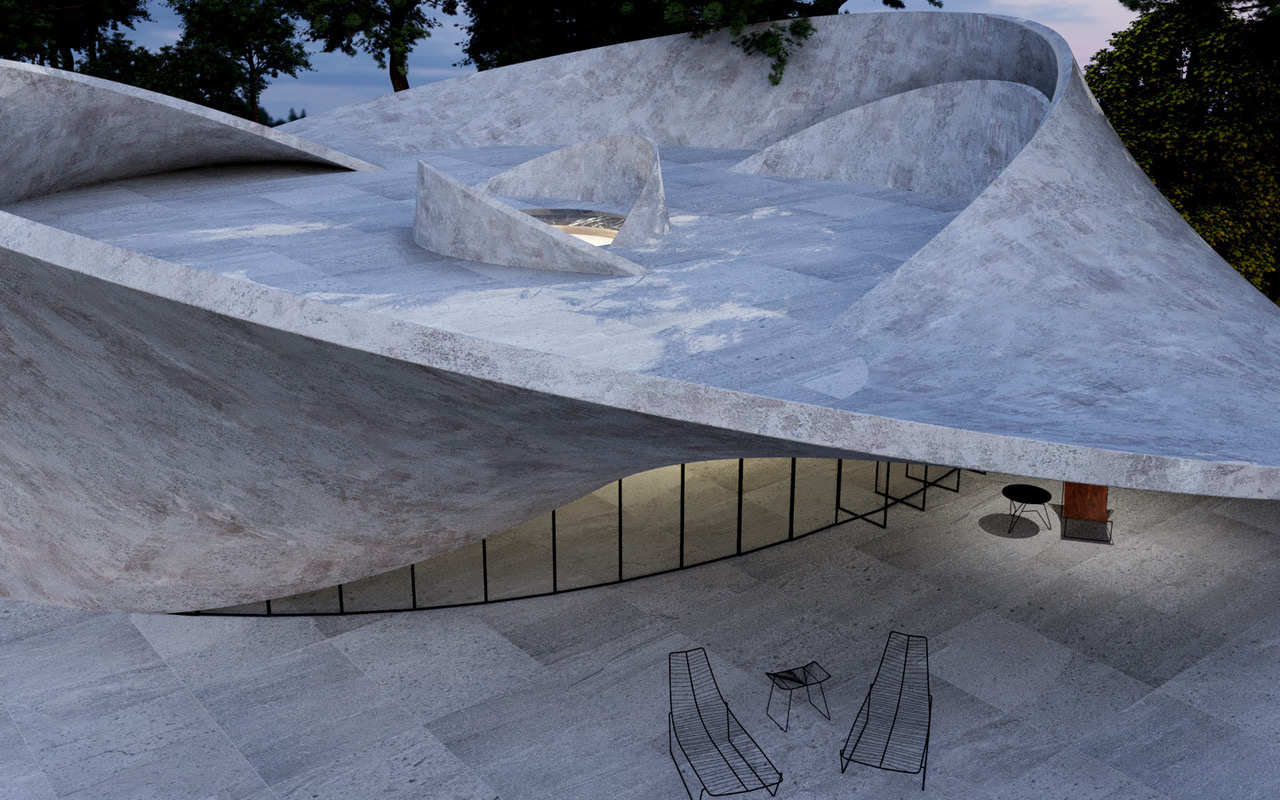

Mobius House of Hemp Bricks and Concrete | Gibbons Design

Image by Antony Gibbons

This house, designed by Antony Gibbons Design is inspired by the Möbius strip and is entirely made out of hempcrete blocks reinforced with concrete, which expresses the house’s connection with nature. The structural design and material choices are an innovative response to the challenges imposed by both mathematics and architecture. The entire house contacts the floor only through few meters, while the roof rigidifies the entire frame of the building. The interior is daylit through the floor-to0ceiling windows facing the swimming pool.

Courtesy of Steffen Welsch Architects

Designed by Steffen Welsch Architects, Hemp House in Australia is a dual occupancy home that provides a unique experience of co-housing. Hemp House is made of natural materials: timber, rammed earth, and hempcrete—it is the first hempcrete house in Australia.

The use of such natural materials gave the designers an opportunity to get adventurous with sculptural curves, and more importantly, build in an environmentally friendly manner. The designers’ vision of the environment goes beyond heating and cooling, it included aesthetics, acoustics, and air quality. This is why hempcrete was a perfect choice for such vision, it is breathable, it regulates temperature and humidity, it is an effective acoustic insulator, and it creates a cozy and warm atmosphere.

-

Pierre Chevet Sports Center | Lemoal Lemoal

Photography is by Elodie Dupuy

Paris Studio Lemoal Lemoal built France’s first hempcrete public building. The studio took the Pierre Chevet Sports Center as an opportunity to experiment with hemp as a construction material. Structure-wise, the building is carried by a wooden half-vaulted frame that is adjoined to the hempcrete walls for support. This system makes maximum use of the column-free interior, which is a demand for a sports center.

Another demand for such a building is acoustic insulation, which, as previously mentioned, hempcrete walls perform very well regarding. This is one of the reasons why the designers left areas of the hempcrete walls untreated. They also wanted to showcase the hempcrete blocks, which were assembled dry and connected through an interlocking system that requires no adhesives or mortar. Moreover, the hemp panels were harvested and fabricated within 500 kilometers from the sports center’s site, which minimizes transportation emissions.

-

Flat House | Practice Architecture + Material Cultures

Photography by Oscar Proctor

Located at Cambridgeshire in the United Kingdom, Flat House is a “radically low embodied carbon house” as explained by the architects. This house was designed with an aim to create a prototype for pre-fabricated hemp-based construction for more and broader use of hempcrete.

The architects, engineers, and material specialists collaborated to develop a prefabricated panel infilled with hemp that is harvested 20 acres of the farm. This collaboration led to the creation of a brand new hemp fiber cladding product, and more importantly, the establishment of Material Cultures, a research organization whose aim is to explore biomaterials in the context of off-site construction.

-

Regional House Edeghem | BC architects

Courtesy of BC Architects

This community center in Belgium located within a public park was built to strengthen the current function of the park. The development of The Regional House created an educative and participative experience that explores an ecological and sustainable approach to construction—it served its community even during the construction phase. The materials incorporated into the community center include compressed earth blocks and hempcrete.

The hempcrete is used to insulate the facades and the roof and is left untreated to maintain its breathability, making the building CO2-negative. Even the construction techniques of The Regional House were sustainable; 19000 compressed earth blocks were produced in a 3-week workshop, and 213 square meters of hempcrete were installed in a 2-week workshop by more than 150 volunteers.