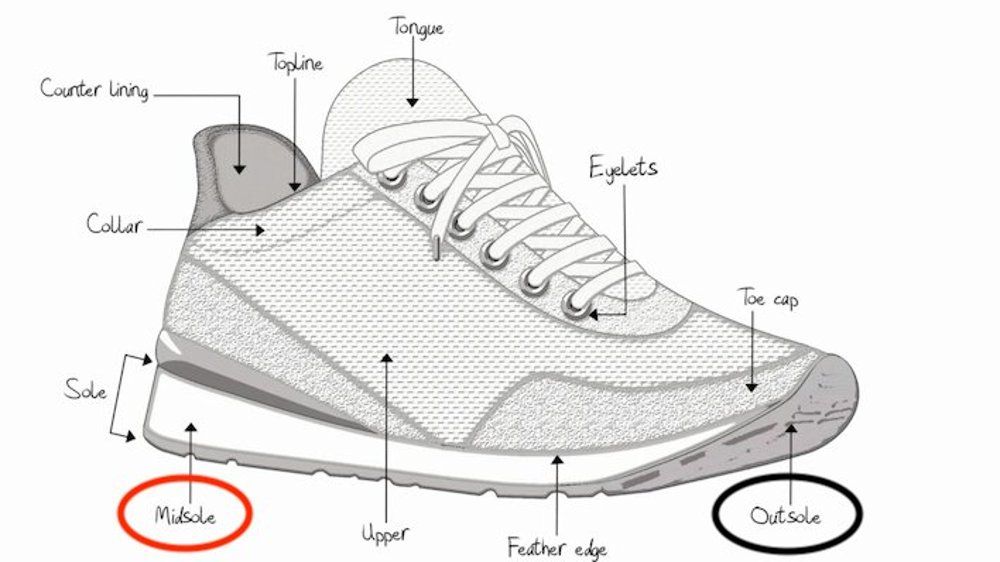

Adidas 3D printed Shoes: 3D printing and innovation have revamped the shoe industry, redefined comfort, and availed us a groundbreaking amalgam of technology and fashion. Something which was used for prototyping primarily has now advanced to a level of individualizing every exclusive commodity. And how far can Adidas lag behind, when it’s about a special pair of shoes, perhaps every athlete’s dream. The new launch from the house of Adidas unveils a unique 3D Printed shoe sole, which matches that of the user’s feet. It’s not been too long since Adidas launched the prior set of designs with Kanye West, Pharell Williams, and Rita Ora, or collaborated with Zaha Hadid and designed an experimental prototype shoe with recycled plastic. In a world where no two feet are similar (not even the ones that belong to the same person), imagining a customized technology such as this one is nothing less than an acid test. This hybrid design ‘ Futurecraft ’, actually reflects the future of the shoe industry. 3-D-printed foam-like substance replaces the conventional ethylene vinyl acetate (EVA) insole and midsole.

The Design of the Adidas 3D printed Shoes:

Like memory foam used by NASA, this flexible and poriferous membrane too is conceptualized and engineered to support any foot to the fullest, by abiding the contours of one’s foot. This specific cushioning base under the heel and forefoot helps to attenuate the landing shock and loading forces experienced while running. Designed in accordance with the footprint of an individual, every customized shoe is one of its kind. Made by a multi-layer fretwork, this membrane is actually 3D printed in collaboration with Materialise, a leading specialist in the world of 3D printing. Futurecraft 3D is a prototype and a statement of intent. We have used one of its kind combination of process and material in an entirely new way. Our 3D printed mid-sole not only allows us to make great running shoes but also to use performance data to drive truly bespoke experiences, meeting the needs of any athlete.

Futurecraft 3D is a prototype and a statement of intent. We have used one of its kind combination of process and material in an entirely new way. Our 3D printed mid-sole not only allows us to make great running shoes but also to use performance data to drive truly bespoke experiences, meeting the needs of any athlete.

– Eric Liedtke, Adidas

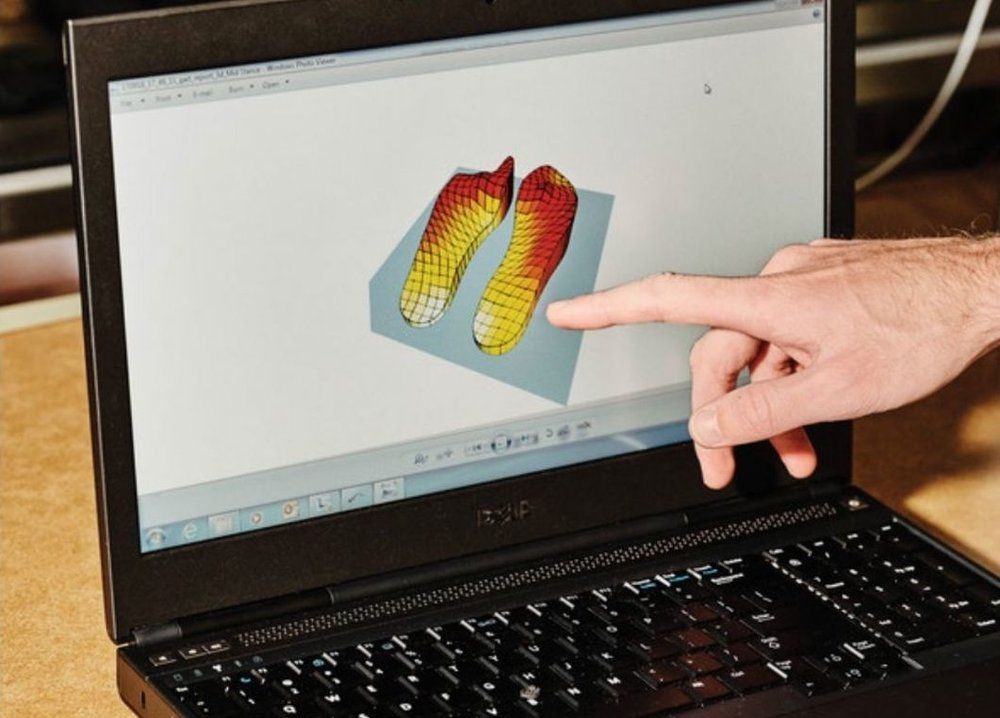

Though the product is exclusive and still subjected to development and improvisation, it marks a threshold in the history of the footwear industry. The best part of the technology is that every customer who’s willing to buy it has to work out a short routine on the treadmill, while his feet are being mapped minutely on a 3D contour grid. This also involves computerized documentation of pressure points and load mechanism of each foot. 3D printing not only ensures the quality of the fabric and knitted intricacies, but also the integration of handcrafting and aesthetics. Futurecraft is our sandbox. It is how we challenge ourselves every day to explore the boundaries of our craft. Driving material and process innovation, bringing the familiar into the future. Marrying the qualities of handcrafting and prototyping with the limitless potential of new manufacturing technologies. Futurecraft is stripped back – fast, raw, and real – it is our approach to design.

-Paul Gaudio, Creative Director, Adidas

This engaging update from Adidas is enough to fuel our wait, for the astonishing innovations yet to be launched in the upcoming months.

By: Khushboo Vyas