Something occurred to me the other day. I have been finding more and more instances where paradigm shifts or hints at them come up in conversations. Here is such an instance. The previous century was, for mankind, the century of figuring out how to use materials to the maximum. We used iron, and when that was no longer strong enough, we used steel. We combined steel’s strength in bending, with cement’s resistance to compression and made modern day concrete construction.

But we’ve since plateaued. Mankind is finding fewer and fewer new ways of using the materials we know, and more and more tried and tested methods. Now it’s probable that if one were to poll contractors, they would say this is great news. But humans strive for innovation and as such, the paradigm of ‘more and more tried-and-tested’ is one that quickly grows stale in our mouths. We are slowly slipping into the paradigm of figuring out how to make our materials to make the things we want. The difference is astounding. No longer will the statement go, ‘yeah, we could probably make that work in steel- it’s gonna need a lot of trussing though’. Instead we are looking at responses more akin to, ‘Yeah, our Poly-_____-ilate will handle that no problem… Unless it’s in a northern climate. In that case, you’re gonna want to use Iso-________-icate.’ We approach an age of making the things we want both directly, in making our materials; and secondary, in making this with those materials.

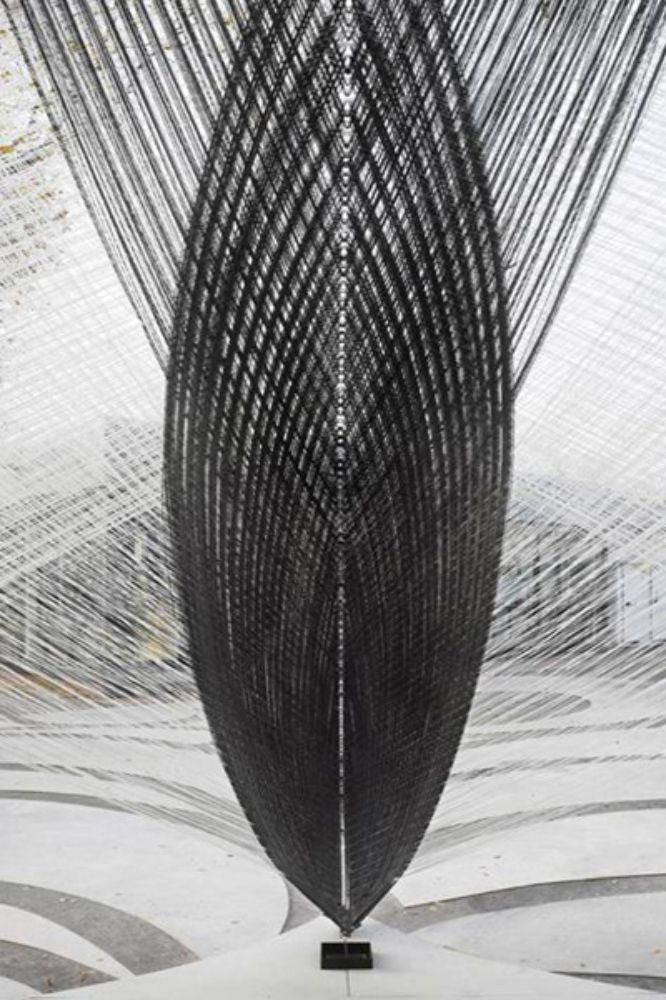

This is a project recently completed by ITKE – Institute of Building Structures and Structural Design, and their partners at the Institute for Computational Design (ICD) at the University of Stuttgart. Below is a brief explanation of the project,

The project demonstrates the latest developments of an integrative computational approach to architectural design, biomimetic engineering and robotic manufacturing. It is the world’s first architecture built entirely by robotic carbon- and glassfibre winding. The research pavilion is entirely constructed from more than 30 kilometers of carbon- and glass fibre with no need for any other supporting building elements. The 4 millimeter thin shell achieves a span of more than 8 meters and in total weighs less than 320 kg… The focus is on bio mimetic design strategies for performative morphology in architecture. Specifically, the structural morphology of natural fibre-composites as found in the exoskeletal cuticula of arthropods, are transferred into a carbon-fibre and glass-fiber reinforced composite lay-up through a custom robotic filament placement process. The project will be located on the University’s campus in the city centre of Stuttgart and is scheduled to be opened at the end of August 2012. The robotic filament placement will happen on-site in a custom fabrication setup, which was developed as part of this project.

A steel starburst-like scaffold was used for the above mentioned robotic assembly to wrap around. The precision used is quite unbelievable. The pavilion and robot would rotate and revolve, acting cumulatively, and even with the slight shuttering of the whole apparatus as the piece stopped spinning, the robot found just the right slot to lay the fibers in. It is technologies like this, and 3D printing which will define construction of the future.

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE

Courtesy of ICD-ITKE