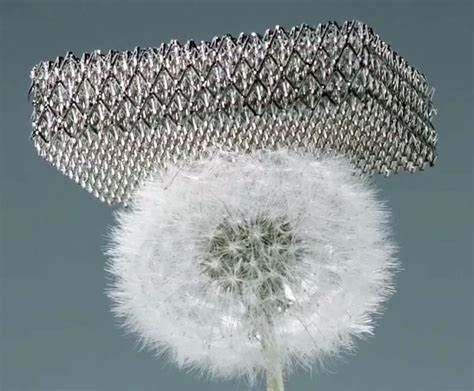

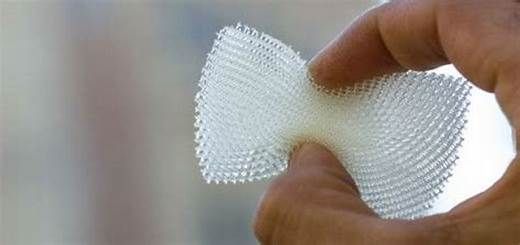

Lightest Material Ever Created by HRL Laboratories + Boeing: every day, experiments are being done, technology is being challenged and as a result, new revolutionary concepts and ideas are coming up at an unimaginable speed. Bright human minds have been relentlessly trying to stretch the boundaries of nature and science while staring defiantly at the ‘impossible’. An example of this is a new video that has surfaced on the internet. HRL Laboratories in collaboration with Boeing have come up with the structure for what they claim to be the Lightest material on the planet, Microlattice. Microlattice was first revealed in 2011 but it is now that someone has come up with a structure that uses it. This material is 100 times lighter than Styrofoam and yet strong. HRL Laboratories have come up with the structure made of a lattice of interconnected metallic hollow tubes having a criss-cross diagonal pattern. The outer surface is not plane solid as there are openings all over the form.

The structure is a 3D open-cellular polymer in which 99.9% of the volume is occupied by air and yet it doesn’t lose its property of bending and twisting. It is not dense at all and has a great center of mass as it can rest atop a dandelion. Even more exciting is the fact that it has properties like heat transfer as well as shock absorption. According to a press release by HRL Laboratories “In addition to its ultra-low density, the material’s cellular architecture gives rise to unprecedented mechanical behavior for a metal, including complete recovery from compression exceeding 50% strain and extraordinarily high energy absorption………………. We are revolutionizing lightweight materials by bringing this concept to the level of the material and designing their architectures at the nano and micro scales” According to Sophia Yang, a Research Scientist at HRL laboratories explains that this structure is quite similar to that of a bone. On the outside is rigid whereas, on the inside, there is an open-cellular structure that provides strength while keeping the material light. The same concept has been used to develop the Microlattice structure. Boeing is excited about the applications it could have in the automobile as well as the aerospace sector. This material substantially decreases the weight of aircraft as well as automobiles thus increasing fuel efficiency. Although it is not supposed to take place of aluminum and steel in the structural aspect of carriers, it could still be used in the internal components. The above-mentioned applications are just the crust of the potential of this substance and one can be very sure with the way science and technology have been exponentially pushing the envelope, that day is in the near future when Microlattice will come out of research labs and be a part of our daily life.

All images courtesy of HRL Laboratories

By: Vaibhav Sharma

courtesy of HRL Laboratories

courtesy of HRL Laboratories

courtesy of HRL Laboratories

courtesy of HRL Laboratories

courtesy of HRL Laboratories

courtesy of HRL Laboratories