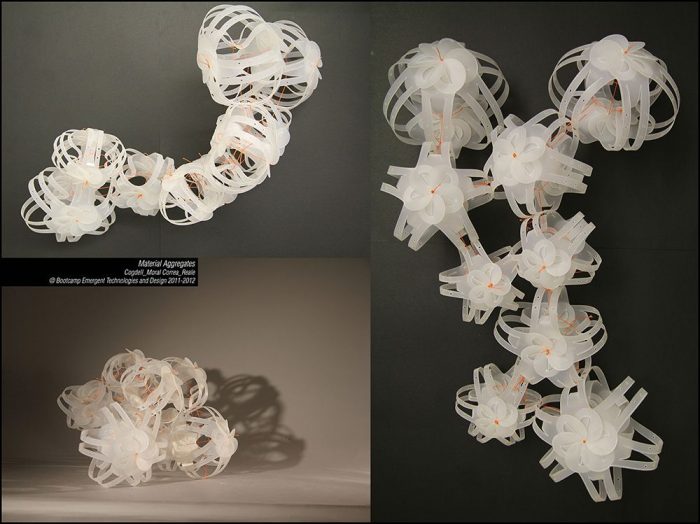

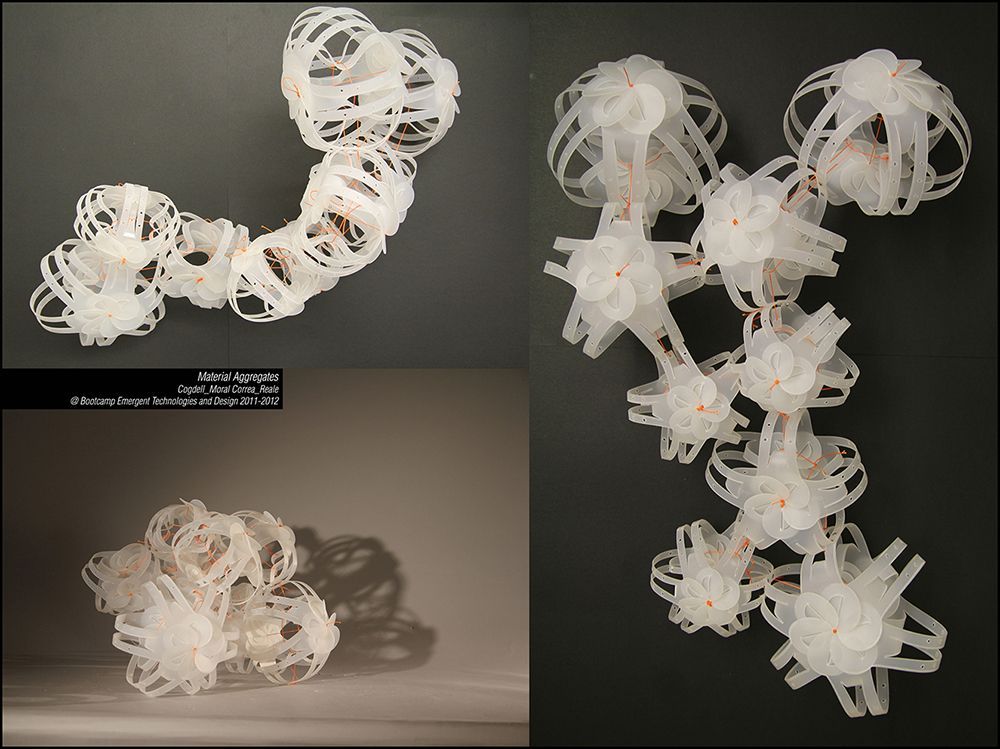

The brief for this project required transforming sheet material into three-dimensional base components aggregated at progressively larger scales. The geometry and material properties of the base component informed its connection to other components, as well as the geometry and assembly logic of the whole, moving back and forth between material and digital explorations.

Owing to the choice to combine base components to create base units, different combinations led to different base units at the local scale. At the regional and global scales, units from different families were combined in order to benefit from differentiation, one of the fundamental requirements for emergence.

The effects of forces on the behavior of the primary material units were analyzed. Early studies relied upon physical weight applied onto individual units to test their stiffness under compression. The ways in which this force was distributed and balanced across connected units by the cable tensioner system were diagrammed.

Proliferations of these components were eventually digitally tested in order to define the global shape of a surface. Attractor points and geometric constraints were utilized as influence for the thickness and the density of the proliferations. In turn, different size of components were produced, listed and organized for the production.

The digital exploration allowed to interpolate some aspects of the potential physical behavior of the systems, as well as proliferate sample surfaces in relation to the proposed final installation. Changes in thickness and porosity of the surfaces were devised to relate to external environmental conditions such as light and heat so that its performance would enhance the spatial utility of the environment.

Credits:

Vincenzo Reale, Christina Cogdell, Mara Moral Correa

Emergent Technologies and Design [AA EmTech] [Vincenzo Reale]

Courtesy of Emergent Technologies and Design

Courtesy of Emergent Technologies and Design