For over seventy-five years, Metal Cladding has established itself as a frontrunner in providing applied coating technologies that improve functionality and market longevity at the lowest possible price.

The metal cladding has been welcomed by the likes of “metal cladding master” Frank Gehry, Richard Rogers, and Renzo Piano for its formal versatility and polish. Its widespread appeal stems mainly from the fact that it can be used in various cutting-edge and mainstream contexts.

What is Metal Cladding?

Any building, from a barn or stable to a fancy office complex, will likely have cladding on its façade, providing long-lasting protection from various climatic hazards, including rain, snow, wind, sleet, ice, and even ultraviolet rays Although cladding can be made from multiple materials, metal cladding is often the preferred substrate because of its attractive appearance, valuable features, and numerous other benefits.

Metallurgy is the field where the practice of metal coating is carried out. Different metals are heated to exceedingly high temperatures to clad a building in metal, poured into molds, and then allowed to cool.

Chemicals are added to the metals during mixing to guarantee a strong chemical bond. Cladding metal requires specialized machinery and experienced workers, so the process is almost exclusively performed in industrial metallurgy facilities.

Also Read: How to Choose from the 10 Best Facade Cladding Materials?

Metal Cladding Materials

There is a wide variety of metal covering options, all of which have advantages and disadvantages. The ideal appearance, weather conditions, structural form, adjacent materials, and building budget are just a few factors that will inform your material choice for a particular project. Among the most frequently used metal covering materials are:

1) Aluminum Cladding

Cladding systems made from aluminum are typically simpler to manually handle and transport due to the material’s lightweight and high strength. The material’s versatility and low cost could account for aluminum’s widespread use in remodeling projects. Considering its low density, it can easily be used as an over-cladding on the current structure.

Also Read: 8 Buildings that Incorporate Wood Cladding and Kinetic Facades

2) Steel Cladding

Of the four options, steel is the strongest and least expensive. A polymer lacquer (such as polyester or plastisol) is typically applied to avoid rust and oxidation. Many different tones are available for coatings, giving designers more freedom.

Profiled steel sheets are used extensively in agriculture and industry because of their low price. The steel sheets won’t warp as much and will have more structural strength thanks to the profiling. This added durability is advantageous in agricultural and industrial settings, where impacts and mishaps are more common.

3) Copper Cladding

For decades, copper has been a staple in the construction industry. Copper cladding is highly sought after due to its natural ability to withstand corrosion, and the dramatic color changing that occurs as the material ages and develops in its environment.

A progression follows copper’s primary red color through increasingly dark brown as the metal acquires a protective coating. Once the copper’s outer layer has been completely oxidized, the metal will continue exhibiting its distinctive green tone for many years.

Also Read: Why is Terracotta Cladding one of the best choices for your contemporary facade?

4) Zinc Cladding

Zinc is a material praised for its resistance to weather and rusting; it is unaffected by ultraviolet light and has self-healing characteristics, meaning it recovers from scratches over time. Zinc cladding darkens from its initial light grey and takes on bluer tones as a patina emerges over time.

Metal Cladding Performance Factors:

Metal’s sturdiness makes it a desirable cladding material. Metal building envelopes can significantly increase the lifespan of a building by using high-quality materials and careful attention to detail. However, to make the most of metal’s benefits, you need to take into account some efficiency factors:

- Sturdiness: Longevity is increased because of metal cladding’s resistance to corrosion and decay. As a bonus, its tremendous strength makes it resistant to impacts like severe weather or unintentional breakage.

- Fire Resistance: Metal construction is inherently more fire-safe than other types of construction, which can save lives in a disaster.

- Weatherproof: Metal cladding is resistant to water penetration and other climate conditions destruction since it’s strong enough to endure snow, rain, high winds, and infrared rays.

- Adaptability: Metal is available in various colors and finishes, making it easy to customize the look and feel of your building envelope. It can also be used for interior and exterior surfaces for added flexibility.

- Soundproof: When appropriately applied, metal cladding can act as sound insulation, making for a calmer space overall.

- Temperature Protection: The thermal properties of metal aid in keeping the building at a consistent temperature, reducing heating and cooling expenses and improving occupant convenience.

- Wind Resistant: Metal cladding can withstand the effects of weather and even improve the building’s stability in stormy conditions, helping prevent losses from severe weather.

- Eco-Friendly: Metal cladding is better for the environment than other materials because it can be recycled, and its manufacturing requires less energy. With this, you can lessen the environmental impact of your endeavor.

Finishes for Metal Façade Panels

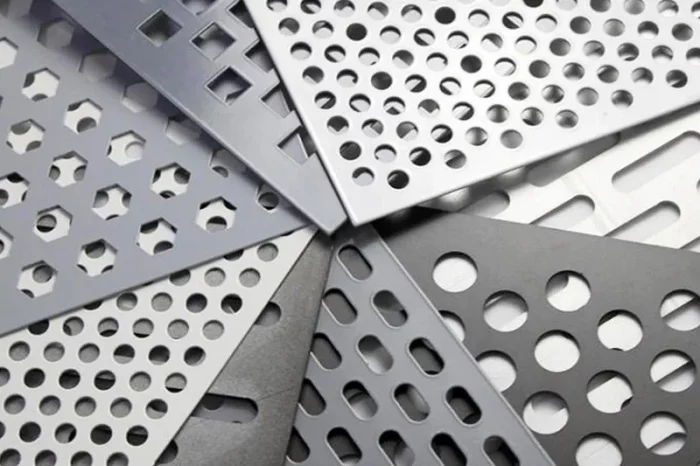

In addition to the layout, your building’s looks can be modified through the use of a variety of different finishes. The most common finishes are polished, smooth, natural, grainy, ribbed, perforated, monotonous, oxidized, and lacquered. Your preferences and financial constraints influence which option is ideal for your structure. Here are some of the most frequently encountered finishes:

1) Painted

Metals that have been polished or darkened have a uniform slick finish and a smooth texture that differs in intensity according to the roughness used during production.

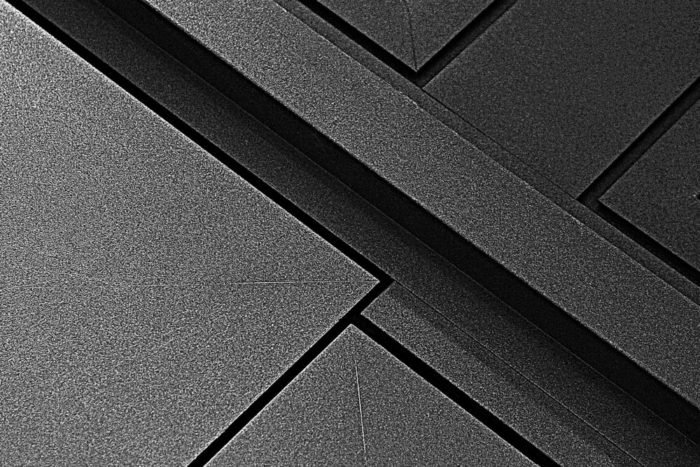

2) Sandblasted

Metals blasted with sand take on a flat, smooth, almost entirely substanceless appearance. Because of its weakened protective barrier, sandblasted steel may rust unless coated with a particular anti-corrosion layer.

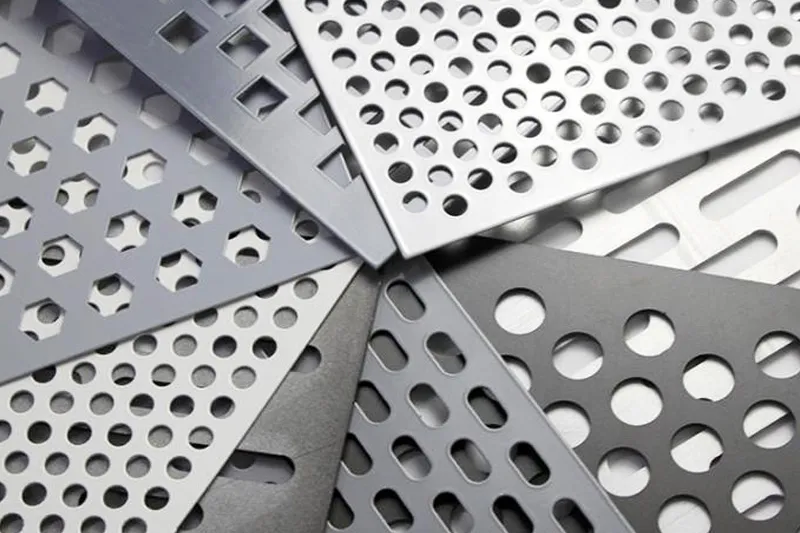

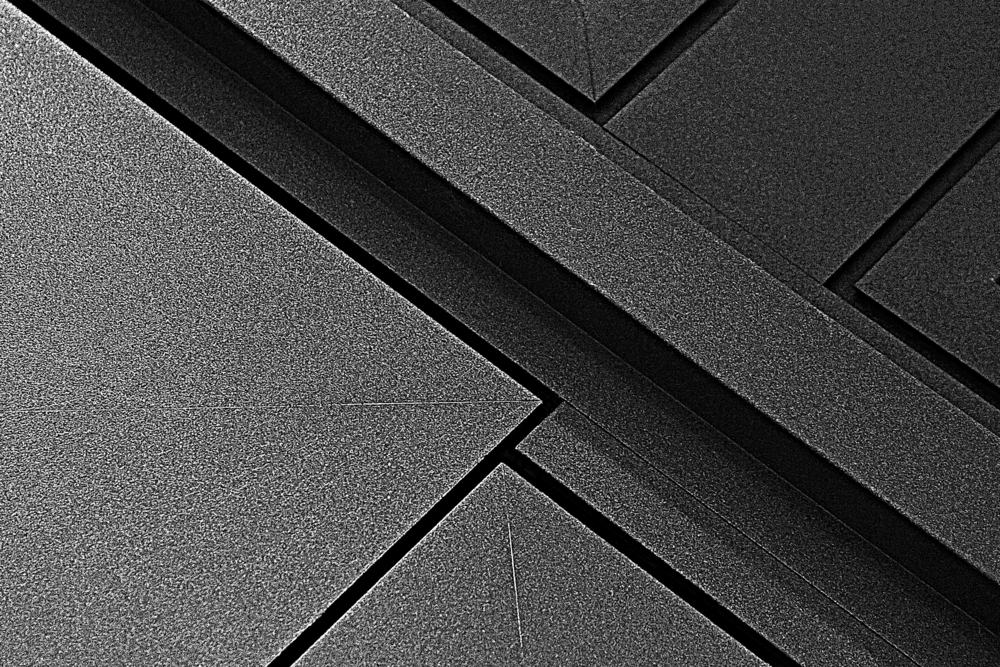

3) Patterned

This is for you if you want a livelier metal wall covering option. These meticulous patterns and bright finishes offer stunning choices in various hues.

4) Engine turned

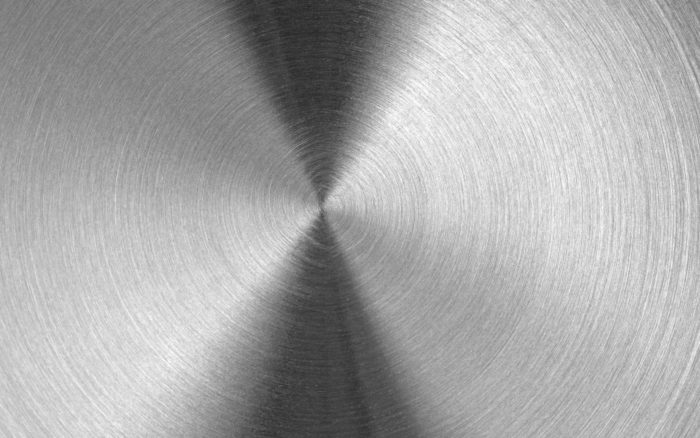

These finishes feature delicate geometric designs engraved into the metal, giving it a twisted aesthetic with different shiny properties.

5) Replicated

Perfectly reflective finishes, also known as “Mirrored metal finishes,” are the most mirrored of all finishes. While they are aesthetically pleasing, they require frequent polishing to keep their sheen.

6) Covered in Powder

Provides metal with a coating of protection and a consistent, smooth texture. There are countless hue options for powder-coated FINISHES.

Metal Cladding Examples

Because there is a wide variety of metals and cladding systems, reference studies can be a handy resource for architects during a project’s design, planning, and configuration phases. In your quest for the perfect metal cladding product, keep in mind the following characteristics, which span cutting-edge material applications, high-quality performance, and striking visual effects:

1) Eastern Gateway Apartments, West Bromwich / Metal Solutions Limited

The design team showed bravery in using color, shape, and form to create a tiered, multicolored, and visually arresting façade. The various cladding options break up the façade and make a clear commercial versus residential expression, both accomplished.

2) Aurubis Nordic Green, Northwest London / Metal Solutions Limited

Property owners in Northwest London took advantage of the growing demand for outdoor rooms by constructing a uniquely shaped addition to conceal their living quarters. The architects sought a copper cladding material to enhance the building’s form and blend in with the neighborhood.

Since getting a green coating from the elements on natural copper can be lengthy, Meta Solutions provided Aurubis Nordic Green. This pre-patinated copper provides an aged appearance right after installation.

3) 18 Buckhold Road (The Bronze), London / Akzo Nobel Powder Coatings Ltd

Cladding for rain screens was given a striking metallic copper finish explicitly created for this project. The finish needed to reflect the area’s industrial past, as it was once home to a sizable copper smelter, per the client’s specifications.

4) The Curve / Metalline Architectural Fabrications

The Curve is Slough’s leading cultural center and the focal point of a £450 million revitalization project. The famous building has a custom cladding system curved in the floor plan and the cross-section. To give the structure a contemporary and high-quality look, all the panels and soffits were finished in a polyester powder-coated metallic silver to provide this aluminum cladding with a magnificent appeal.

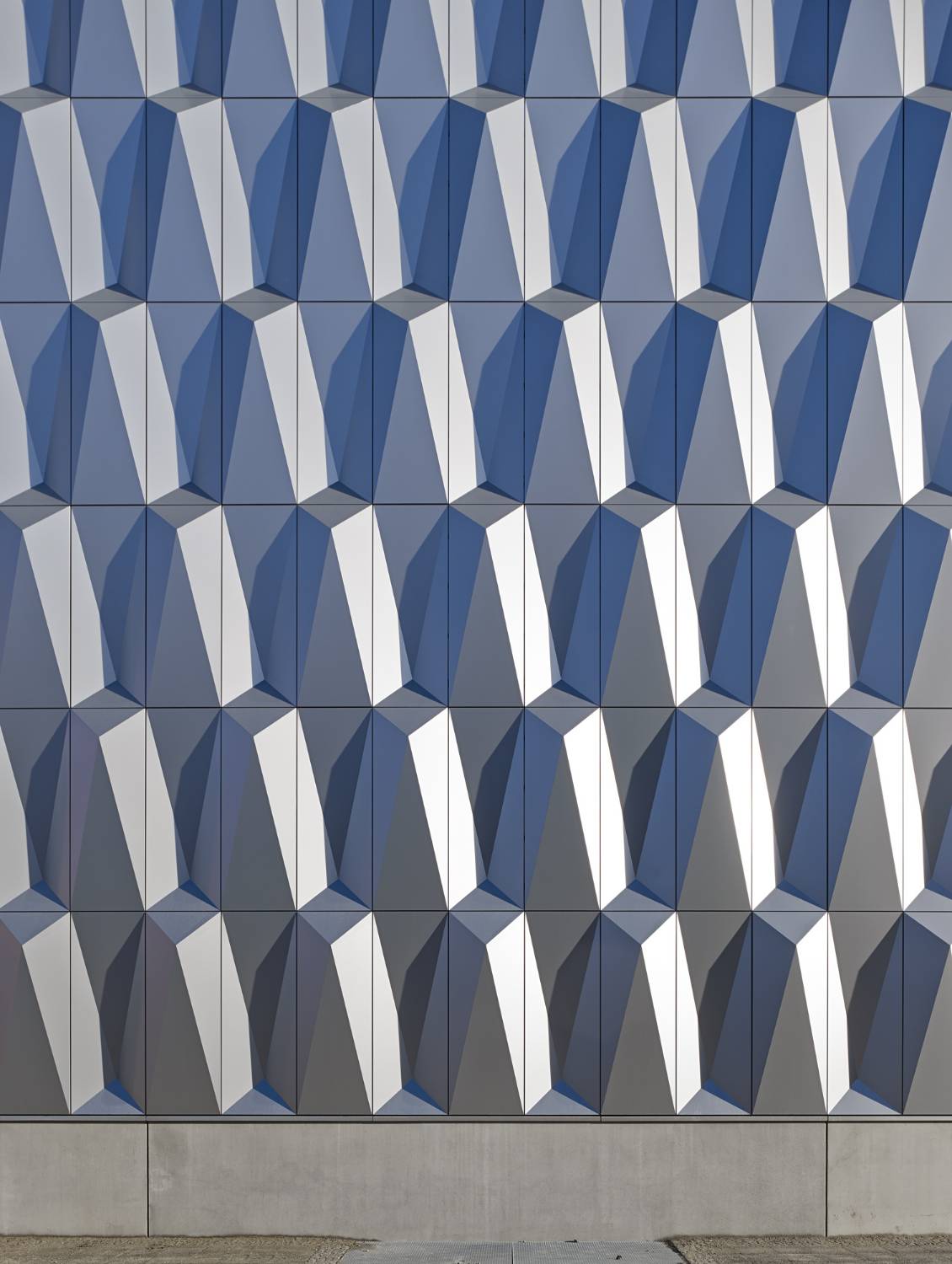

5) Bauhaus / Müller Reimann Architekten

The new Bauhaus AG building, designed by Müller Reimann Architects, is a storehouse with a floor area of 22,000 square feet and an opulent three-dimensional façade metal cladding made of modular tray panels.

The façade’s impact is achieved through the mixture and juxtaposition of various elements, including reflective surfaces, advertising lines, a winter garden, and plants. Not only does it reflect light, but its color shifts as the weather and the time of day cause various light encounters to fall upon it.

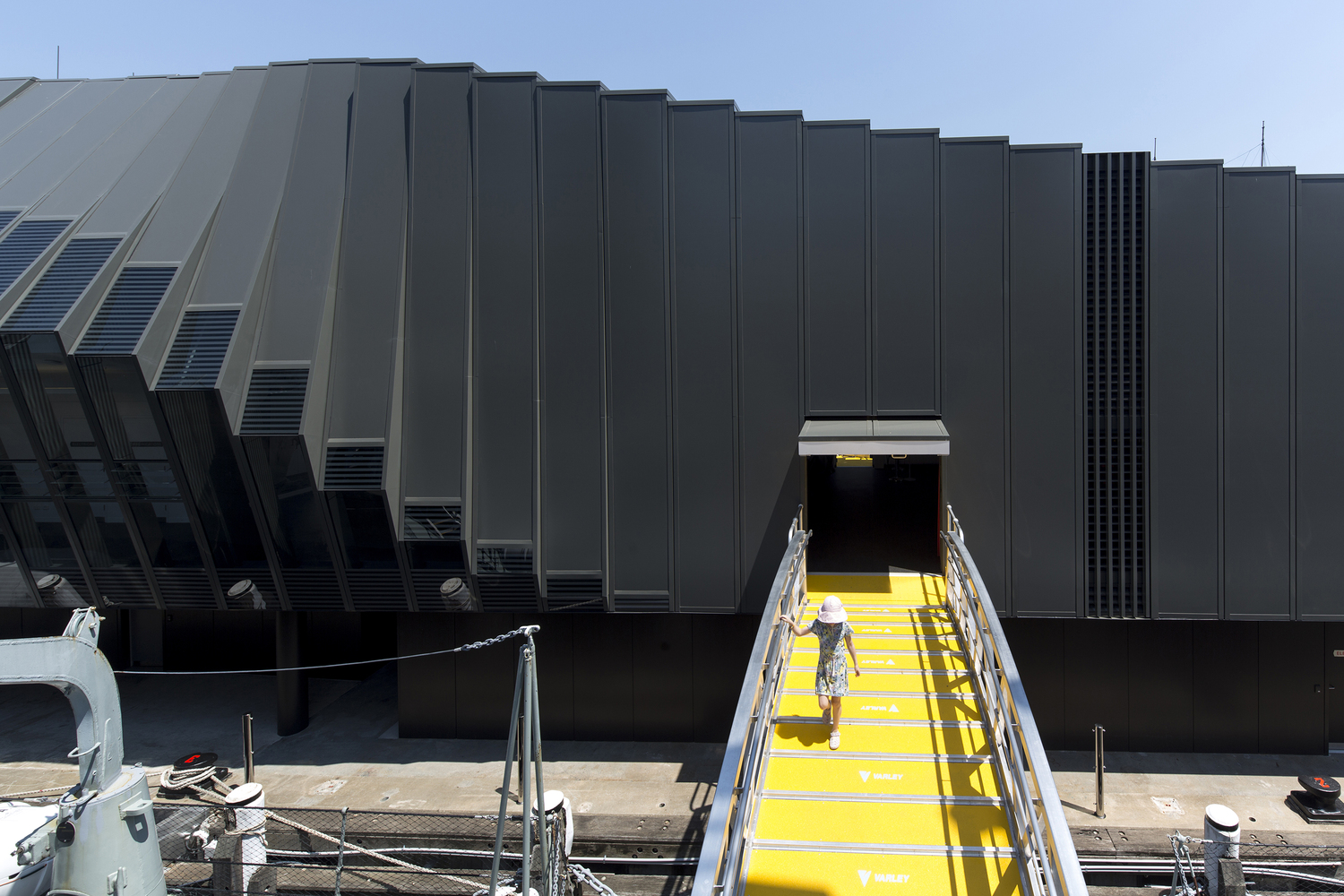

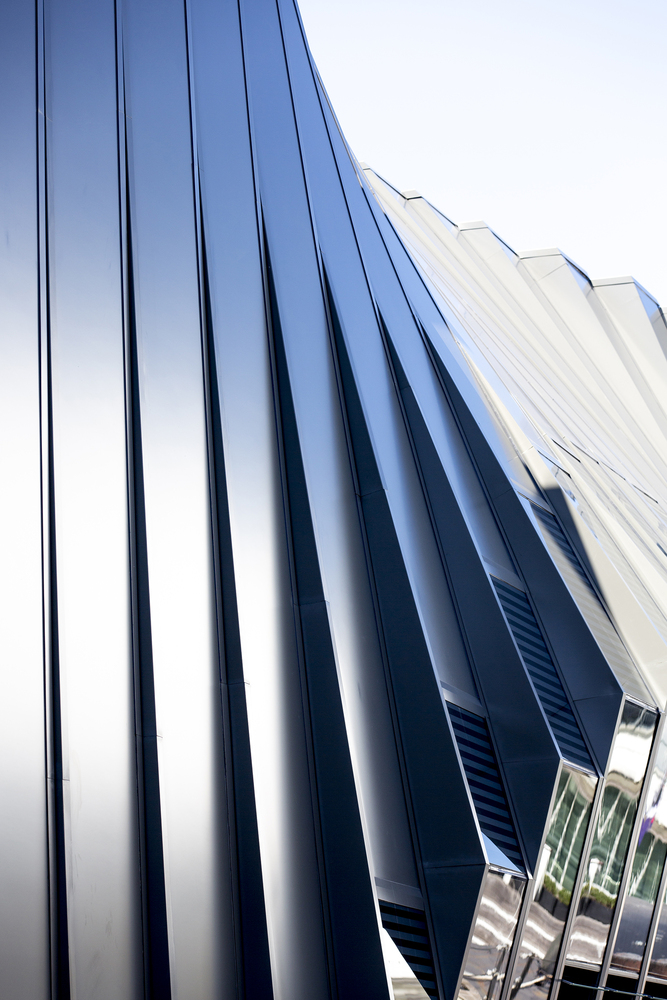

6) The Waterfront Pavilion – Australian National Maritime Museum / FJMT Studio

This enormous waterfront structure has the appearance of being made from curved perforated material, which contributes to its sloping shape. Instead, the slanted façade is formed by big metal cladding slices angled at different degrees. Kingspan, an industry leader in advanced composite material (ACM) cladding and engineered façade systems, collaborated with the architect to bring this unique design to life.

7) Moose Road / Mork-Ulnes Architects

Eagle Rock, a neighboring mountain ridge, and the surrounding vineyard valley can all be seen from within the comfort of this home. The primary difficulty came from balancing the client’s desire for sustainability with the restrictions of their funding and the three perspectives they wanted to present. Sheet metal from All Weather Architectural Aluminum, provided in standard sizes, was used to construct the structure.