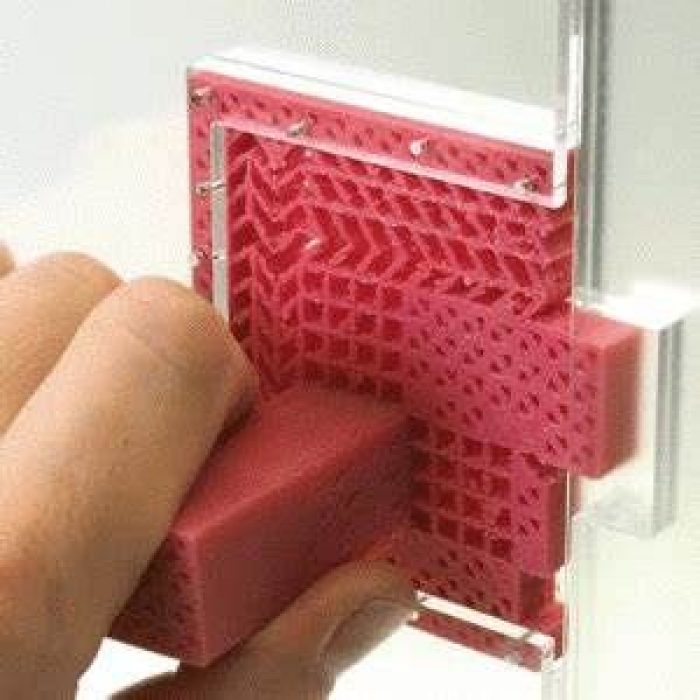

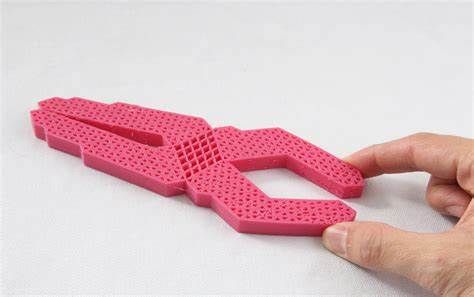

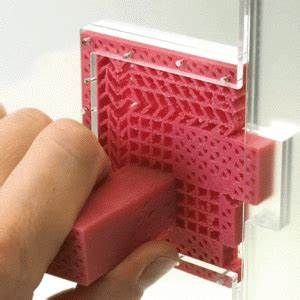

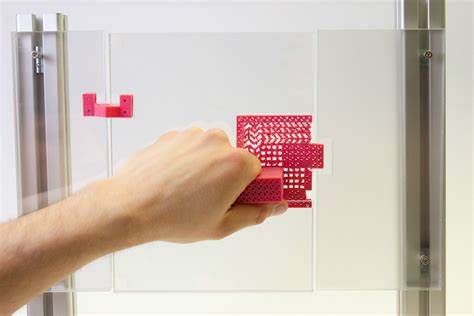

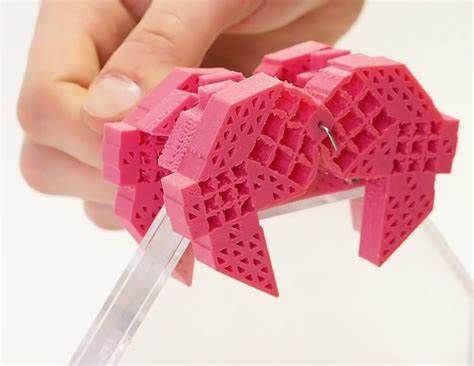

Developed by a team at Hasso Plattner Institute’s Human Computer Interaction Lab, the new technology called metamaterials is used by scientists and researchers to create various mechanisms from 3D printed object despite being printed as one single part. A door latch and a pair of pliers were created using this technology and without any screws, bolts or other fixings. This technology is type of engineered material defined by its internal structure rather than what substance it is made of. It also have properties that are not found in nature, as with the real-life “invisibility cloak”. The 3D printed objects can have controlled directional movement, meaning that they can perform set mechanical functions, like gripping something or latching a door. “The ultimate vision is to design the inside of objects,” Hasso Plattner Institute researcher Patrick Baudisch said, adding: “We can use this to give objects unexpected functionality. ” The new technology cut out the need for a printed mechanism to be assembled from multiple or fiddly pieces as the metamaterial mechanisms are made up of grids of silicone cells with different patterns to create different levels of rigidity. The more flexible cells can shear, causing the rigid portions they touch to move with them.

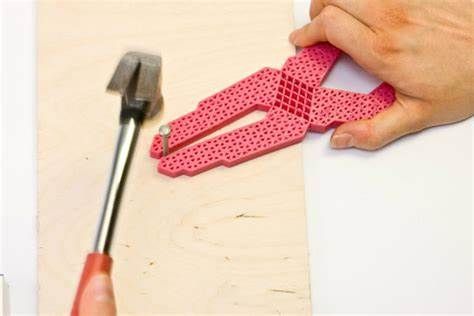

Previous experiments have made objects display unusual behaviors in response to force, but metamaterial produced projects make advances in forming accurate mechanisms. “Since these objects allow each cell to be designed differently, the resulting objects literally offer thousands of degrees of freedom,” said the research team in a paper. Custom 3D editing software is used to create the metamaterials mechanisms. This software runs element analysis to predict the mechanism of objects when forces are applied in specific areas like pushing in a door handle when creating a door latch mechanism. For this example of a door latch, to create it using the new technology, they firstly lay down the rigid blocks of the door latch and then add flexible, shearing cells around it. Because the mechanisms are 3D-printed as a single part in flexible silicone, alternatively ABS or PLA plastic, they do not require assembly, nor do they need lubrication to move which, according to the team claims, will reduce the need for maintenance. Elastic materials that can withstand high forces without breaking can be used for Metamaterial mechanisms. Accordingly, researchers suggested spring steel as an ideal material option to be used although it is still not possible to be fabricated using today’s 3D printers. Although 3D printing technology is yet not very common within households, it is creating lots of potential for researcher. Lots of structures have been 3D printed ranging from homes to bicycles and wheelchairs, in addition to 3D printed artificial hair which its 3D printing methods were developed by researchers at the Massachusetts Institute of Technology (MIT), while on the other hand, 3D printed concrete was printed by students at Bartlett School of Architecture to create concrete.