ProtoHouse by Softkill Design

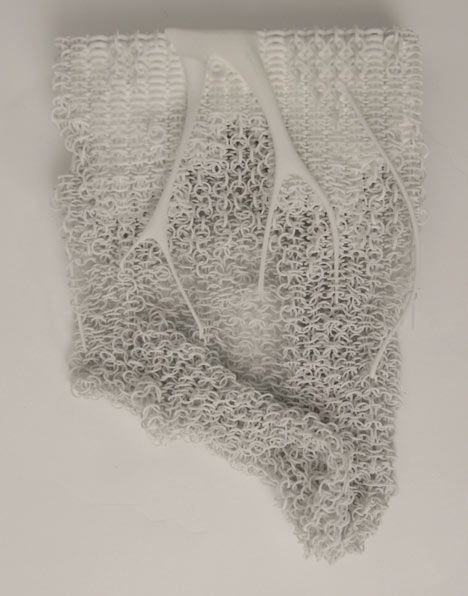

Some of the most sturdy architectures known, are those created by nature. Animal bodies, with their sinews and muscle fibers contain immense strength in unassuming forms.

In the previous century construction techniques were those of just that, construction. With progressing technological developments, came progressions in do-ability and material economy. But with 3D printing now thoroughly on the scene, it appears that future construction will be a process occupied with synthesis. Our bodies grow organically, compounding upon what’s already there, creating collective strength- it is likely that our future buildings will follow a similar growing process.

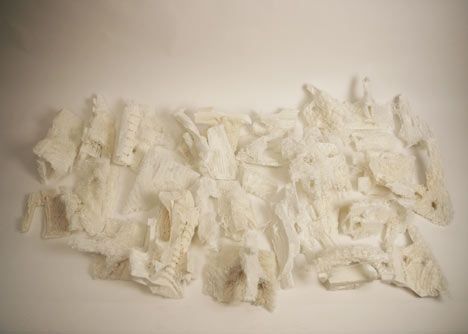

Softkill Design, a collaboration between Nicholette Chan, Gilles Retsin, Aaron Silver and Sophia Tang, has recently completed ProtoHouse, a prototype for the first 3D printed house, which rides the forefront of this new paradigm. Created using Selective Laser Sintering technology, a printing process with the benefit of needing no additional support scaffolding (sintered material is surrounded by un-sintered powder which acts as a self-scaffold), the ProtoHouse is able to be constructed as a series of 30, finely detailed fibrous units- which are able to be assembled without adhesives. In a scaled up, full-size version, these parts could be printed off-site and easily transported by truck for site assembly. ProtoHouse is printed at 1:33 scale. The fibers are .77mm in radius. With these sinews creating form and collective strength, it becomes possible to create a more inclusive architecture with furnitures and features incorporated into the form and body.