It was long ago, around the 15th century, when Johannes Gutenberg invented the printing press and brought on the Renaissance. People marveled at the new revolutionary technology. Not quite as long ago, precisely in the second half of the 20th century, inkjet and laser printing were developed, and printers have become quite common ever since. They have become handier, smaller in size, cheaper, and faster, and they no longer belonged to publishing houses and big establishments alone.

All sorts of workplaces, now, cannot give up the services of a printer, and most households already have one. After conquering the world of 2D printing, it was about time to move it to the next level and tackle 3D Printing which is now one of the Architectural Innovative Technologies All Architects Should Know.

What is 3D Printing?

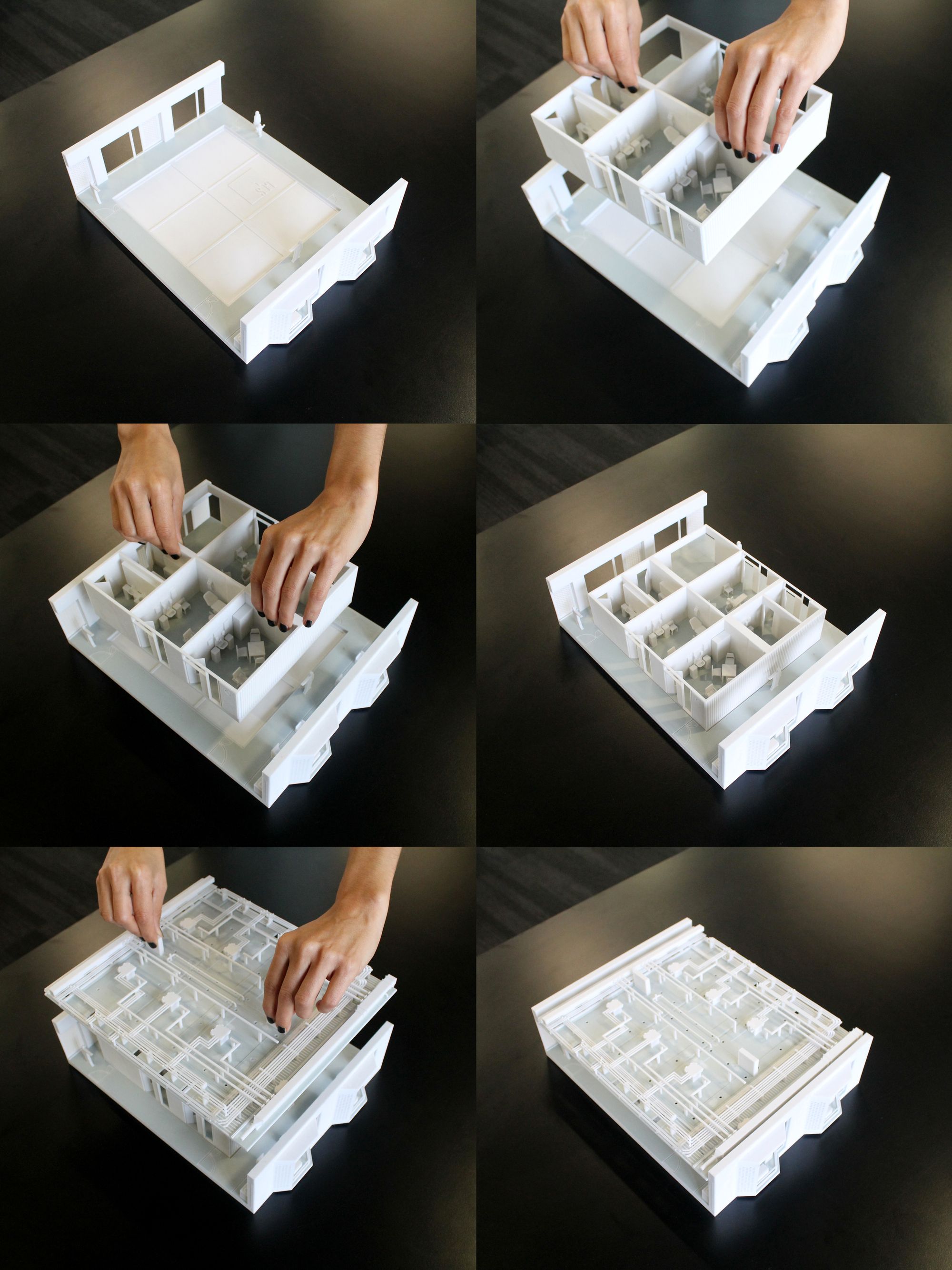

University College London Hospitals, Phase 5 interior model, London (UK). Image © Steffian Bradley Architects

Also known as Additive manufacturing, 3D printing is one of the latest innovations in the field of printing and it exactly does what it says; it prints 3D forms. 3D printers print one layer above the other creating a third dimension for the 2D drawings on the computer screen. Special computer software applications are used to prepare designs and data for 3D printing.

3D printers were first invented in the 1980s and since then, inventors have been introducing new techniques for printing and using various materials to get optimum products.

What is 3D Printing used for?

3D Printing has a wide range of applications in all sorts of fields. For example, it can be used in the food industry to print custom-shaped candy. It can be used for medical purposes, like creating exact replicas of body organs and prostheses for the disabled.

It, also, has applications in the fields of fashion and Jewelry design, where outfits, shoes, and accessories can be printed for prototyping or mass production. And in the field of the automotive industry, manufacturers have successfully used 3D printers to compose entire parts of cars and airplanes.

However, what concerns us, as architects are the applications of this technology in the fields of construction and architectural design:

- Architects can, now, create high-quality models, much faster and with less effort. They can flexibly present their designs and ideas using a wide range of materials

- Some building parts can, also, be 3D-printed and used in construction.

- Renowned firms and designers have built pavilions and small structures using 3D-Printing technology.

- Some companies have even attempted to 3D-print entire edifices. Chinese engineering corporation WinSun is one of these daring practices that fully printed more than one building. Those buildings are not inhabited, so we cannot exactly say if they “worked”. However, experts claim them to be safe and reliable.

- 3D-printed furniture is also a “thing”, and it is even proving more widely implemented than 3D construction. Famous designers have experimented with the technology to create customized chairs, tables, and benches. The products of the combination between 3D printing and parametric design have turned out to be quite impressive and unique.

What Materials can be used for 3D Printing?

-

Resin

can be used for detailed designs and sculptures. It provides a smooth surface finish and sharp edges. It is not available in a variety of colors, but it can be easily painted.

-

Nylon Plastic

is white in color. It has a wide range of applications due to its flexibility and strength, and it has a sandy granular surface finish.

-

Metals

include aluminum, bronze, chromium, gold, silver, titanium, and stainless steel. They are laser-sintered from metal powder, and they have high strength. They can be used to manufacture functional mechanical parts or Jewellery.

-

Gypsum/Sandstone

is rigid and brittle but characteristic of its colored texture. It can be used to create architectural models, product designs, and fine artworks.

-

Acrylonitrile Butadiene Styrene (ABS)

is a thermoplastic used commonly for mold injections? It is highly durable and heat resistant. Its applications include automotive parts and the popular LEGO bricks.

-

Polylactic Acid (PLA)

is an eco-friendly option since it is obtained from renewable resources. It is a biodegradable thermoplastic, created from potato starch, cornstarch, or sugar cane. It is used for food packaging, disposable garment, and most importantly for surgical implants.

What are the possible advantages of 3D Printing?

As we can see, 3D printing is widely spreading but it has not revealed its full potential yet. If the technology proves to be as useful as anticipated, then it would be advantageous, compared to other construction techniques, in terms of productivity. It will be more dependent on robotics and so, it will require less labor. Accordingly, construction costs will go down.

3D printing will also make it possible to build almost “anything”. Any complicated forms that may have seemed unrealizable before will be possible to achieve, or print, with the aid of CAD software and 3D Scanners.

What are the possible advantages of 3D Printing?

3D Printing may be an initially expensive option. It will also need skilled experts who can deal with robotics and technical details to operate.

Current 3D printers produce limited sizes for parts, and they can print only one piece at a time. The products of 3D printing could, also, require further treatment and processing to be presentable.